In the fast-paced world of electronic assembly, where every connection counts, finding the perfect soldering solution can make all the difference. That’s where Kester steps in, revolutionizing the industry since 1899 with their unrivaled expertise and innovative products. From solder pastes to fluxes, wire to preforms, Kester has mastered the art of creating solid, sturdy bonds that withstand the test of time. Join us as we delve into the realm of Kester solder, uncovering a treasure trove of knowledge, reliable products, and a commitment to excellence. Get ready to elevate your soldering game and unlock the true potential of precision.

Product Offerings of Kester

When it comes to soldering, having the right tools at your disposal can make all the difference. Kester understands this need and offers a diverse range of high-quality solder and solder-related products. With their commitment to excellence and decades of industry expertise, Kester has become a trusted name in the world of electronic assembly. Let’s explore their impressive lineup of products that cater to the needs of professionals and hobbyists alike.

Solder Pastes

Kester’s solder pastes are formulated to provide exceptional performance and reliability. These pastes are designed for various soldering applications and ensure precise, consistent, and robust solder joints. Whether you’re working on surface mount technology (SMT) or through-hole assembly, Kester’s solder pastes deliver the results you need.

Fluxes

Flux is an essential component in soldering, aiding in the removal of oxides and ensuring proper wetting of surfaces. Kester offers a wide range of fluxes suitable for different soldering applications. Their flux formulations provide excellent solderability, reduced bridging, and minimal voiding, resulting in superior solder connections.

Wire

Kester’s wire products are available in both flux-cored and solid forms. Flux-cored wire simplifies the soldering process by combining the flux and solder into one convenient package. Solid wire provides excellent control and versatility, allowing for precise soldering in various applications. You can achieve reliable and durable solder joints with Kester’s solder wire.

Preforms

For precise and controlled soldering applications, Kester offers solder preforms. These pre-cut and shaped solder pieces provide consistent solder volume and controlled placement, ensuring accuracy and reliability in intricate soldering tasks. Kester’s preforms are available in various sizes and alloys to meet your requirements.

Bar Solder

Kester’s bar solder is a versatile option for soldering applications that require a manual application. Available in different alloys, these bars offer ease of use and excellent solder flow. Whether you’re soldering large components or performing hand-soldering tasks, Kester’s bar solder provides the reliability and quality you need.

PC Fabrication Chemicals

Kester understands the importance of a clean and well-prepared surface for successful soldering. Their PC fabrication chemicals include cleaners, etchants, and surface treatments that ensure optimal adhesion and solderability. You can achieve pristine surfaces and reliable solder connections with Kester’s PC fabrication chemicals.

Residue Removers

After soldering, removing flux residues is crucial to maintain the long-term reliability of your assemblies. Kester offers residue removers that effectively clean and remove soldering residues, leaving your circuits and components spotless. These residue removers are formulated to be safe and efficient, saving you time and effort in the cleaning process.

Lead-Free Solder

With the increasing demand for environmentally friendly solutions, Kester provides a range of lead-free solder options. These solder products comply with industry regulations and offer reliable performance without compromising on quality. Kester’s lead-free solder ensures solder joints that meet the highest quality standards and environmental responsibility.

Kester’s solder and solder-related products are available for purchase through various retailers. You can find them at trusted distributors such as Mouser Electronics, Amazon, and GoKimco directly through Kester’s website. With its extensive network of retailers, obtaining the right soldering products from Kester is convenient and accessible.

Kester offers an extensive product lineup that caters to the diverse needs of soldering professionals and enthusiasts. Whether you require solder pastes, fluxes, wire, preforms, or any other soldering essentials, Kester’s range of high-quality products ensures exceptional performance and reliability. Explore their offerings and experience the difference that superior soldering tools can make in your projects.

Practical Experiences with SnCu-Based Solders

In the realm of soldering, achieving reliable and durable solder joints is a top priority. Kester Solder recognizes this need and has gone above and beyond to share their practical experiences and insights. One invaluable resource they provide is a published PDF that delves into creating solder joint reliability using SnCu (tin-copper) based solders.

This PDF serves as a comprehensive guide, offering practical insights and real-world experiences that shed light on the intricacies of working with SnCu-based solders. It provides in-depth information on the challenges, techniques, and best practices involved in achieving optimal solder joint reliability.

The significance of this resource cannot be overstated. By delving into the practical experiences shared by Kester, soldering professionals gain access to a wealth of knowledge and expertise that can significantly enhance their soldering applications. Instead of relying solely on theoretical information, the PDF equips soldering enthusiasts with valuable insights derived from hands-on experiences in real-world scenarios.

The practical experiences shared in this resource allow individuals to understand better the nuances and intricacies of working with SnCu-based solder. It covers aspects such as alloy composition, soldering temperatures, joint formation, and the impact of various factors on the reliability of solder joints. By leveraging this knowledge, soldering professionals can make informed decisions and implement strategies that lead to superior solder joint performance and longevity.

Furthermore, the practical experiences shared in this resource provide a bridge between theory and practice, giving soldering professionals the confidence to tackle real-world challenges with precision and expertise. It helps them anticipate potential issues, identify optimal solutions, and ultimately improve their soldered assemblies’ overall quality and reliability.

In conclusion, Kester’s published PDF detailing practical experiences with creating solder joint reliability using SnCu-based solders is a remarkable resource that unlocks the secrets to achieving exceptional solder joint performance. By sharing their experiences and insights, Kester empowers soldering professionals with practical knowledge that can be directly applied to their soldering applications. Embrace this resource, and elevate your soldering capabilities to new heights, ensuring the reliability and longevity of your soldered connections.

The Best Kester Solder Product for Electronic Assembly

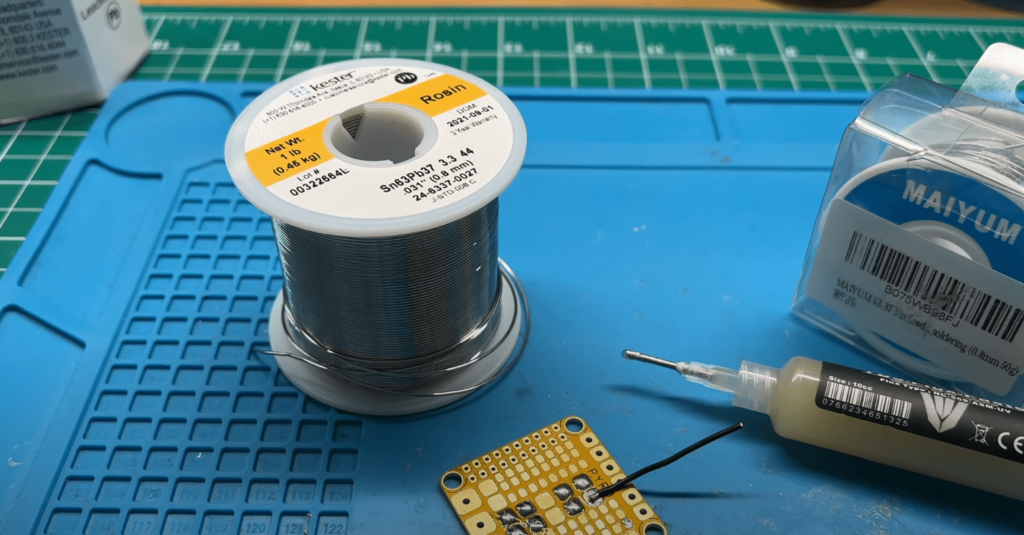

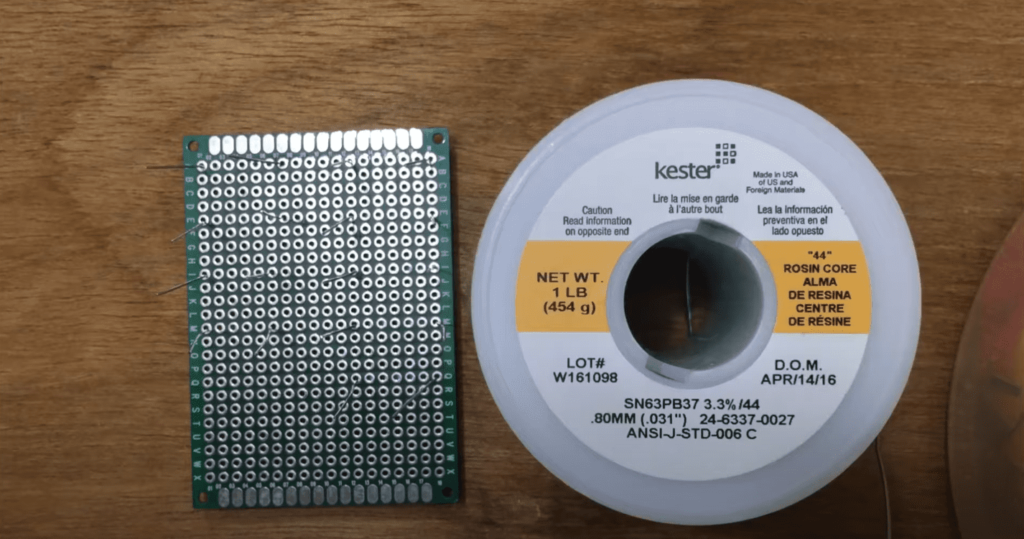

When it comes to electronic assembly, one solder product stands out among the rest: Kester 44 Rosin Core Solder. Renowned for its exceptional performance and reliability, it has become a popular choice among soldering professionals worldwide.

At the heart of Kester 44 is its composition. With a ratio of 63% tin and 37% lead (63/37), this eutectic alloy ensures a low melting point and a solid, sturdy bond. The eutectic composition means that the solder transitions directly from solid to liquid and vice versa at a specific temperature, simplifying the soldering process and producing consistent results. This characteristic makes Kester 44 ideal for various electronic assembly applications.

Consistency and reliability are hallmarks of Kester 44 Rosin Core Solder. With every joint you create, you can expect a uniform flow and a reliable bond that withstands the test of time. This consistency ensures that your soldering projects are completed precisely and efficiently, resulting in high-quality, dependable connections.

Kester has established itself as a well-known brand in the soldering industry, trusted for its commitment to excellence, and used in high-precision soldering jobs. When you choose Kester 44 Rosin Core Solder, you tap into the expertise of a brand that has stood the test of time. From intricate circuit board soldering to delicate electronic component connections, Kester’s reputation as a reliable and trusted brand ensures that your soldering needs are met with the utmost professionalism and precision.

Whether you’re an experienced professional or a hobbyist venturing into the world of electronic assembly, Kester 44 Rosin Core Solder is the go-to choice for achieving outstanding results. Its 63/37 composition, low melting point, and solid bond make it an exceptional solder for various applications. With Kester’s trusted reputation, you can confidently embark on your soldering projects, knowing that you have chosen a product that delivers consistency, reliability, and the exceptional performance required for high-precision soldering jobs.

Composition of Kester 63/37 Solder

At the core of Kester’s soldering excellence lies the composition of their renowned 63/37 solder. Composed of 63% tin and 37% lead, this eutectic alloy has become a staple choice for electronic assembly due to its exceptional properties and reliable performance.

One of the key advantages of Kester 63/37 solder is its low melting point. Being a eutectic alloy, it undergoes a phase change directly from solid to liquid and vice versa at a specific temperature. In the case of Kester 63/37, this temperature is approximately 183°C (361°F). This low melting point allows for efficient and controlled soldering, minimizing the risk of heat damage to sensitive electronic components.

The solid and sturdy bond achieved with Kester 63/37 solder is another reason for its popularity in electronic assembly. When properly applied and heated, the molten solder forms a strong and reliable connection between components, ensuring optimal conductivity and mechanical strength. The solid bond created by Kester 63/37 solder provides long-lasting performance and withstands the rigors of various applications.

It is worth noting that the composition of Kester 63/37 solder is directly linked to the popularity and reliability of Kester 44 Rosin Core Solder. Kester 44, a widely recognized and trusted product in the soldering industry, incorporates the 63/37 composition. The consistent and reliable performance of Kester 44 can be attributed to the eutectic nature of the 63/37 alloy, which ensures precise melting and solidification, resulting in consistent and robust solder joints.

The popularity and reliability of Kester 44 Rosin Core Solder further reinforce the trust soldering professionals place in the composition of Kester 63/37 solder. Its proven track record and extensive usage in electronic assembly applications have made it a go-to choice for those seeking high-quality, dependable solder connections.

In summary, the composition of Kester 63/37 solder, consisting of 63% tin and 37% lead, offers numerous advantages for electronic assembly. Its low melting point enables controlled soldering while minimizing heat damage. The solid and sturdy bond it forms ensures long-lasting performance and durability. The popularity and reliability of Kester 44 Rosin Core Solder, which shares the same composition, underscore the value and effectiveness of the 63/37 alloy. With Kester 63/37 solder, you can confidently tackle your electronic assembly projects, knowing that you have a reliable and trusted solder that delivers consistent and robust solder joints.

FAQ

Is Kester the best solder?

The determination of whether Kester is the best solder depends on various factors, such as specific application requirements, personal preferences, and individual experiences. Kester is a reputable and well-established brand in the soldering industry, known for producing high-quality solder products. However, there are other reputable brands as well that offer excellent solder options. It is recommended to consider factors such as alloy composition, melting point, reliability, and suitability for the intended application when choosing the best solder for a particular project. Conducting research, reading reviews, and considering individual needs will help determine the best solder for a specific situation.

Is Kester solder made in the USA?

Yes, Kester solder is made in the USA. The company was founded in Chicago in 1899 as the Chicago Solder Company and has a long-standing history of manufacturing solder and solder-related products in the United States. Kester’s commitment to quality and innovation has made them a trusted American brand in the soldering industry.

What is Kester solder used for?

Kester solder is used for a wide range of applications in the field of electronics and electrical engineering. It is primarily used for creating reliable and durable electrical connections by joining components on circuit boards, wires, or other electronic assemblies. Some common applications of Kester solder include:

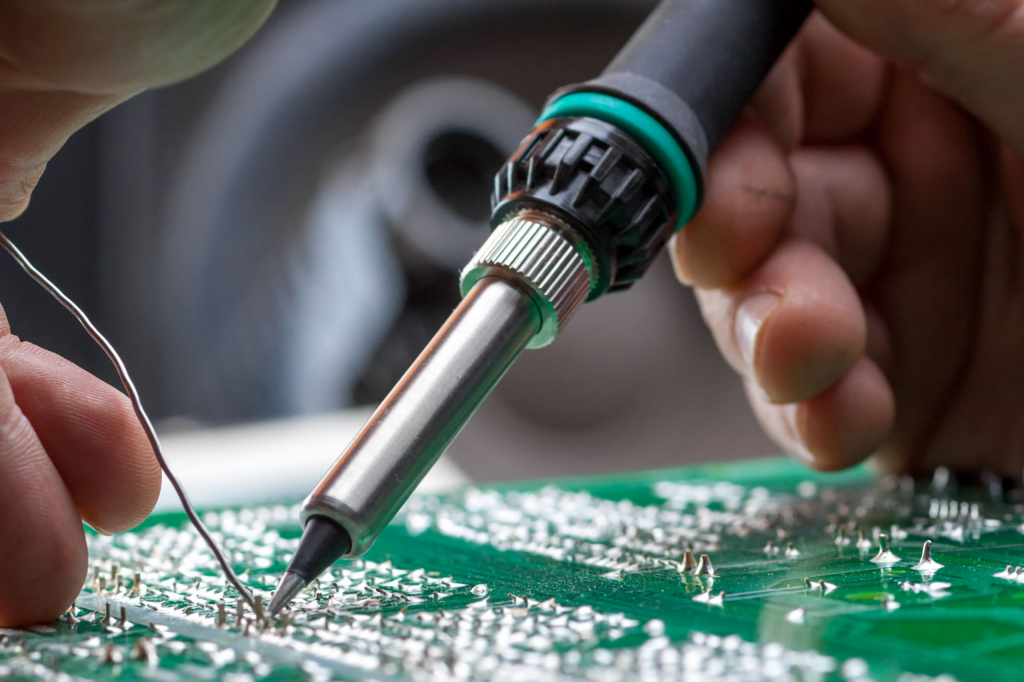

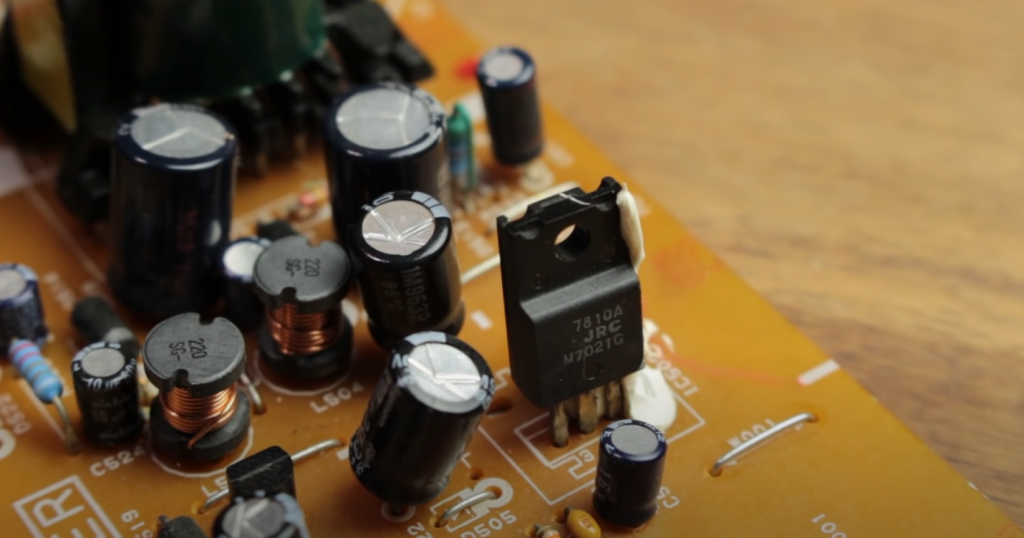

- Printed Circuit Board (PCB) Assembly: The solder is used to attach electronic components to PCBs, creating electrical connections and enabling the flow of current between them.

- Wire and Cable Termination: The solder is used to join wires and cables, ensuring secure electrical connections and preventing signal loss or intermittent connections.

- Electronic Repairs and Rework: Solder is utilized to repair or replace faulty or damaged electronic components, such as soldering new components onto a PCB or repairing broken connections.

- Electrical and Electronic Manufacturing: Kester solder is used to produce a wide range of electrical and electronic devices, including consumer electronics, industrial equipment, automotive electronics, and telecommunications equipment.

- Soldering in Hobbyist and DIY Projects: Kester solder is also popular among hobbyists and DIY enthusiasts who engage in various electronics-related projects, such as building electronic circuits, assembling kits, or creating custom electronic devices.

With its reliable performance, consistency, and durability, Kester solder is trusted by professionals and hobbyists alike for achieving high-quality solder connections in diverse electronic applications.

How long does Kester solder last?

The lifespan of Kester solder depends on usage, environmental conditions, and proper handling. With correct application and storage, Kester solder can maintain its effectiveness for a long time (2 years and more).

Does Kester solder expire?

No, Kester solder does not have a specific expiration date. When stored properly in a dry and controlled environment, Kester solder can remain usable for an extended time. However, over time, factors such as exposure to moisture or contaminants can potentially impact its performance. Following recommended storage guidelines and inspecting the solder for any signs of degradation before use is advisable.

Related Video: Having Trouble Soldering? This Could be the Reason Why / Don’t Use Cheap Solder Use Kester

Final Words

Kester is a trusted and reputable brand in the soldering industry. They provide solutions for electronic assembly needs with a wide range of high-quality products, valuable resources, and practical insights. Whether you are a professional or a hobbyist, Kester is dedicated to delivering reliability, innovation, and customer satisfaction in every soldering endeavor.