A hot air rework station is a device used to heat and remove electronic components from a circuit board. It is an essential tool for any electronics hobbyist or professional. There are many different models of hot air rework stations on the market, so it can be difficult to choose the right one. In this article, we will recommend the best hot air rework station for you, based on your needs and budget.

Here’s a quick list of what to look for in a hot air rework station:

- Size: Make sure the unit is large enough to accommodate the biggest components you’ll be working with.

- Features: Look for features that are important to you, such as adjustable temperature settings or a built-in vacuum pump.

- Price: Compare prices to find the best value for your budget.

- Safety: Look for a model with a built-in cooling fan and safety trigger to prevent accidental burns.

- Quality: Choose a unit that’s made of high-quality components and designed to last.

X-Tronic 5040-XR3 – Editor’s Choice

Looking for a top quality hot air rework station? Look no further than the X-Tronic 5040-XR3. The X-Tronic 5040-XR3 Hot Air Rework Station is a complete hot air rework station that gives you PID technology for complete digital control of your temperature.

Looking for a top quality hot air rework station? Look no further than the X-Tronic 5040-XR3. The X-Tronic 5040-XR3 Hot Air Rework Station is a complete hot air rework station that gives you PID technology for complete digital control of your temperature.

It is an ESD safe station that has a total power consumption of 1270 watts and a temperature range of 212 F to 896 F. The X-Tronic 5040-XR3 Hot Air Rework Station is an all in one soldering, hot air work station that is perfect for any electronic workbench.

This station has a preheating feature that makes it ideal for working with sensitive components. The temperature range is 122 F to 752 F, making it perfect for a variety of tasks. The auto cool down feature is a great safety feature that keeps the station from overheating.

Quick 861DW Hot Air Rework Station – The Best for Power

Quick 861DW Hot Air Rework Station is a great choice for anyone looking for an affordable and reliable unit. This unit offers 1000 Watts of power and a maximum temperature of 930 degrees Fahrenheit. The 861DW also features a sleep mode, which conserves energy when the handle is placed in the stand.

Quick 861DW Hot Air Rework Station is a great choice for anyone looking for an affordable and reliable unit. This unit offers 1000 Watts of power and a maximum temperature of 930 degrees Fahrenheit. The 861DW also features a sleep mode, which conserves energy when the handle is placed in the stand.

The Quick 861DW is a top of the line hot air rework station that can be used for a variety of purposes. It has a powerful heating element that can quickly heat up, making it ideal for soldering and desoldering components. Overall, the Quick 861DW is a great choice for anyone looking for a high-quality hot air rework station.

YIHUA 862BD+ Hot Air Rework Station – Customer’s Choice

The YIHUA 862BD Hot Air Rework Station is a versatile and reliable tool for a variety of soldering and rework tasks. It features three LED displays for easy viewing, exclusive air gun manual or automatic mode, and adjustable and readable air flow. The PID temperature control technology ensures precise and consistent temperatures, while the 1 year warranty provides peace of mind.

The YIHUA 862BD Hot Air Rework Station is a versatile and reliable tool for a variety of soldering and rework tasks. It features three LED displays for easy viewing, exclusive air gun manual or automatic mode, and adjustable and readable air flow. The PID temperature control technology ensures precise and consistent temperatures, while the 1 year warranty provides peace of mind.

With its many features and affordable price, the YIHUA 862BD is an excellent choice for anyone in need of a hot air rework station.

X-Tronic 6020-PRO-X Hot Air Rework Station

The X-Tronic 6020-PRO-X Hot Air Rework Station is a powerful and versatile tool that can be used for a variety of tasks. The temperature range of 212 F – 932 F makes it ideal for soldering and desoldering components, as well as for heat shrink tubing.

The X-Tronic 6020-PRO-X Hot Air Rework Station is a powerful and versatile tool that can be used for a variety of tasks. The temperature range of 212 F – 932 F makes it ideal for soldering and desoldering components, as well as for heat shrink tubing.

The ESD safe design of the station ensures that delicate components are protected from static discharge. The hot air gun calibration function ensures that the gun is always operating at the correct temperature, and the auto cool down and standby functions help to prolong the life of the station.

The X-Tronic 6020-PRO-X features a patented quick change hot air nozzle rack, making it easy to change nozzles when needed. The hot air gun has fan malfunction protection, meaning that if the fan fails, the gun will automatically shut off. This prevents damage to the gun and keeps you safe.

Aoyue 852A++ Hot Air Rework Station

The Aoyue 852A Hot Air Rework Station is a fully digital control station that allows for easy and accurate temperature and airflow adjustments. With a temperature range of 212-896 F, the 852A is perfect for a variety of soldering, desoldering, and rework applications.

The Aoyue 852A Hot Air Rework Station is a fully digital control station that allows for easy and accurate temperature and airflow adjustments. With a temperature range of 212-896 F, the 852A is perfect for a variety of soldering, desoldering, and rework applications.

The auto sleep function ensures that the unit is never left on accidentally, and the included tip set ensures that you have everything you need to get started.

Aoyue 852A is a professional-grade hot air rework station that can remove and repair surface mounted devices such as SOIC, CHIP, QFP, BLCC, and BGA. It has a 500-watt heating element that makes it powerful enough to handle even the most stubborn components. The digital display makes it easy to set and maintain the temperature, while the automatic cooling system ensures that the unit stays cool to the touch. This hot air rework station is an essential tool for any electronics technician or engineer.

The Buyer’s Guide

When it comes to hot air rework stations, there are a lot of options on the market. So, how do you know which one is the best for your needs? This buyer’s guide will help you narrow down the choices and find the perfect hot air rework station for your needs.

Heat-Up Time

When it comes to selecting the best hot air rework station for your needs, one of the most important factors to consider is heat-up time. You’ll want a unit that can reach high temperatures quickly, so you can get started on your project right away. Here are a few things to keep in mind when choosing a hot air rework station based on heat-up time.

First, consider the type of projects you’ll be working on. If you’re doing simple soldering jobs, you won’t need a unit that heats up as quickly as one meant for more complex tasks. Second, take into account the size of the area you’ll be working on. A small soldering iron tip will require less heat-up time than a large one. Finally, think about how often you’ll be using the hot air rework station. If you’re a professional who is constantly soldering, a quicker heating model will be more useful. If you only use it occasionally, you’ll be fine with a model that takes longer to heat up.

Ability to Control Temperature

There are a variety of different types of hot air rework stations on the market, and each one offers its own set of features and benefits. But if you’re looking for a hot air rework station that will give you the most control over temperature, then you’ll want to consider one that offers digital temperature control.

A digital temperature control system allows you to set a precise temperature for your hot air rework station, and then monitor the actual temperature with an LED display. This ensures that you always have a consistent temperature when working with sensitive electronic components. Most digital temperature control systems also include a built-in safety feature that prevents the unit from overheating.

Safety Features

When choosing the best hot air rework station for your needs, it is important to consider the safety features that are available. Some of the safety features that you may want to look for include:

- An automatic shut-off feature that will turn off the unit if it gets too hot.

- A tip temperature sensor that will prevent the unit from reaching unsafe temperatures.

- A cool-down feature that will help to prevent accidental burns.

By considering the safety features that are available, you can help to ensure that you choose a hot air rework station that is safe for you to use.

Weight and Size

A good hot air rework station will be lightweight and easy to move around. It should also have a sturdy base that will keep it from tipping over.

Another important consideration is the size of the unit. You want a hot air rework station that is large enough to handle the biggest jobs, but not so large that it takes up too much space in your work area.

Nozzle

Hot air rework station nozzle selection is critical. There are a few things to consider when making your decision, such as the size and shape of the nozzle, the material it’s made from, and the airflow.

Size and shape are important because you need to make sure the nozzle is compatible with the component you’re trying to remove. If the nozzle is too small, it won’t be able to generate enough heat to melt the solder. If it’s too big, you run the risk of damaging the component.

The material the nozzle is made from is also important. Some materials are better at conducting heat than others. For example, copper is a good choice because it heats up quickly and evenly. Stainless steel is another popular choice because it’s durable and easy to clean.

Display

There are two different types of displays that these stations can have, so it’s important to know which one will be best for your needs.

The first type of display is an LED readout. This type of display will show you the temperature that the station is set at, as well as the actual temperature that the tip is reaching. This is a great option for those who want to be able to see exactly what’s going on with their station.

The second type of display is a digital readout. This type of display will show you the same information as an LED readout, but it will also have a few other features. For example, a digital display may have a timer and a countdown feature. This is great for those who want to be able to know exactly how long their station has been on for and when it will shut off.

Material

One of the most important things to look for is a metal or sturdy plastic casing. This will ensure that your device is durable and can withstand repeated use. Additionally, you want to make sure that the steel internal components are of high quality. This will help to prevent any damage to your electronic components during use.

Airflow

There are a few things that you need to keep in mind when it comes to airflow and hot air rework stations. First of all, you need to make sure that the station has enough power to create a strong airflow. If not, then you won’t be able to get the job done right.

Another thing to keep in mind is that you need to have a good control over the airflow. If you can’t control it, then you won’t be able to do a good job on your project.

Ease of Use

There are many different features that can make a hot air rework station easier or more difficult to use, so it is important to choose one that will be easy for you to operate.

One important factor to consider is the control panel. The control panel should be easy to read and understand so that you can quickly set the temperature and other settings. It should also be easy to change the settings without having to take your eyes off of what you are working on.

Another factor to consider is the size of the hot air rework station. If you plan on using it in a small space, then you will want to choose a smaller model. If you plan on using it in a large space, then you will want to choose a larger model.

Price

When it comes to finding the best hot air rework station for your needs, price is always going to be a factor. But how do you know if you’re getting the best value for your money? Here are a few things to keep in mind when comparing prices on hot air rework stations.

First, consider the features that are important to you. Some hot air rework stations have more features than others, so you’ll want to make sure you’re comparing apples to apples. If you don’t need all the bells and whistles, you can save money by opting for a simpler model.

Second, take into account the brand reputation. Not all hot air rework stations are created equal, and some brands are simply better than others. Do your research and read reviews before making your final decision.

Finally, don’t be afraid to negotiate. Many retailers will work with you on price, so don’t be afraid to ask.

Warranty

When you are in the market for a hot air rework station, one of the key considerations is what kind of warranty is offered with the purchase. Many companies will offer a limited warranty, often for just 90 days. However, some manufacturers offer more comprehensive warranties that cover the entire unit for up to two years.

If you are looking for the best hot air rework station on the market, it is worth paying attention to the warranty that is offered. A longer warranty period gives you peace of mind knowing that if something goes wrong with your purchase, you will be covered.

When choosing a hot air rework station, be sure to ask about the warranty and what it covers. A good warranty should cover all parts and labor, so that if anything goes wrong, you can get your unit repaired or replaced at no cost to you.

Hot Air Rework Station Brands

There are many different brands of hot air rework stations on the market today. Some of the more popular brands include Hakko, Aoyue, YIHUA, and Newacalox. Each brand has its own unique features and benefits.

Hakko is one of the leading manufacturers of hot air rework stations. Their products are known for their quality and durability. Hakko also offers a wide range of accessories and replacement parts for their rework stations.

Aoyue is another popular brand of hot air rework station. Their products are known for being easy to use and very user friendly. Aoyue also offers a wide range of accessories and replacement parts for their rework stations.

YIHUA is a less well-known brand of hot air rework station, but their products are still very high quality. YIHUA also offers a wide variety of accessories and replacement parts for their rework stations.

Newacalox is a very popular brand of hot air rework station. Their products are known for being high quality and extremely durable. They also offer a wide variety of accessories and replacement parts for their hot air rework stations.

Hot Air Rework Station vs. Heat Gun: What’s the Difference?

When it comes to reworking or repairing electronics, there are a few different ways to go about it. One option is to use a hot air rework station, while another is to use a heat gun. So, what’s the difference between the two?

A hot air rework station blows hot air over the area that needs to be repaired. This can be useful for a variety of tasks, such as soldering and desoldering components, melting and removing old solder, and more.

A heat gun, on the other hand, directs a stream of hot air at the target area. This can be used for similar tasks as a hot air rework station, but it’s generally not as precise. Heat guns can also be used for other tasks such as shrinking heat shrink tubing and removing paint.

So, which should you use? It depends on the job. The hot air rework station is great for tasks where you need a steady stream of heat, but it’s not ideal for shrinking tubing or removing paint. A heat gun is better for these types of jobs.

Hot Air Rework Station vs. Soldering Station: What’s the Difference?

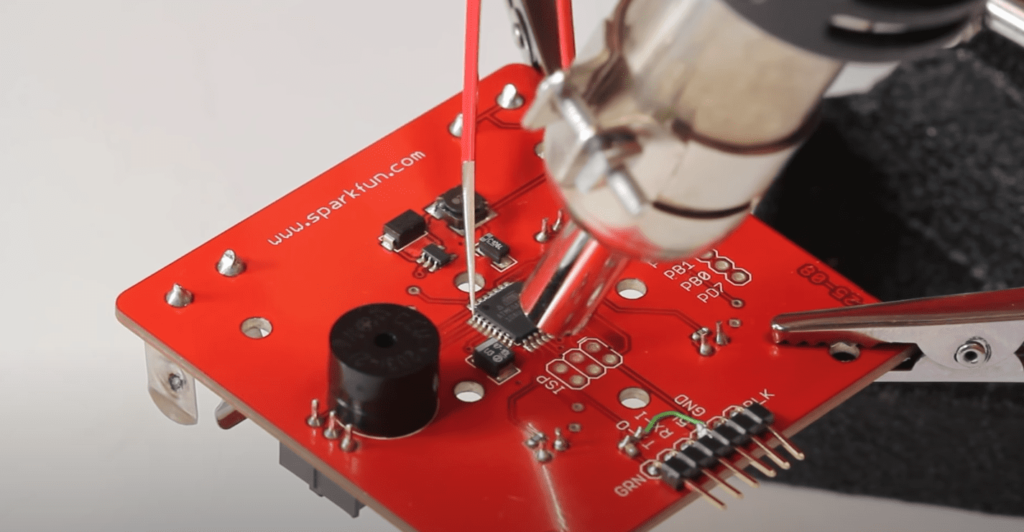

A hot air rework station and a soldering station are both tools that can be used to solder and desolder components from circuit boards. However, there are some key differences between the two.

A hot air rework station uses hot air to solder and desolder components. This makes it ideal for working with delicate components, as there is less risk of damage. A soldering station uses a soldering iron to heat up the components, which can be more damaging to delicate components.

Another difference between the two is that a hot air rework station is typically more expensive than a soldering station. This is because it is a more specialized tool. There are many different tools that can be used to solder and desolder components from circuit boards. If you have delicate components that need to be removed, or if you simply want to speed up production in your manufacturing company, a hot air rework station is a great option for you.

Hot Air Rework Station Alternatives

There are a few different types of hot air rework stations on the market. Some are more expensive than others, but they all have their pros and cons. Here are a few alternatives to the traditional hot air rework station:

The first alternative is the infrared rework station. These types of stations use infrared heat lamps to heat up the area that needs to be repaired. They are faster than traditional hot air rework stations, but they can be more difficult to control.

The second alternative is the laser rework station. These types of stations use a laser to heat up the area that needs to be repaired. They are very precise and can be used for small repairs. However, they are also very expensive.

The third alternative is the ultrasonic rework station. These types of stations use ultrasonic waves to heat up the area that needs to be repaired. They are not as precise as laser rework stations, but they are much less expensive.

FAQ

Do you need a hot air rework station?

A hot air rework station is not strictly necessary, but it can be very helpful when working with delicate electronic components. The station provides a controlled stream of hot air that can be used to carefully heat and remove components without damaging the surrounding circuitry.

What is a hot air rework station used for?

A hot air rework station is used to heat and then cool electronic components in order to remove them from a circuit board.

What temperature should hot air rework station be set at?

There is no definitive answer to this question as it will depend on the specific application and materials being used. However, a general rule of thumb is to set the temperature at around 390 F.

Are hot air rework stations efficient?

Yes, hot air rework stations are efficient. They use a hot air gun to heat up the area around the component that needs to be replaced. The heat from the gun melts the solder holding the component in place. The component can then be removed and replaced with a new one.

Do you need a hot air rework station for a cordless soldering iron?

A hot air rework station is not necessary for a cordless soldering iron, but it can be helpful. A hot air rework station can be used to heat up the area around the soldering joint, which can make the soldering process easier.

What is a BGA rework station?

A BGA rework station is a type of soldering station that is specifically designed for working with ball grid array (BGA) components. These stations typically have features such as precision temperature control and the ability to create a controlled environment around the work area, which helps to prevent damage to the delicate BGA components.

Do you need to ventilate when soldering?

Yes, you need to ventilate when soldering. The fumes from the soldering can be harmful if inhaled.

Is a hot air rework station necessary?

A hot air rework station is not necessarily required for all electronic projects. It can be helpful for certain tasks, such as removing and replacing components on printed circuit boards (PCBs). If you plan to do a lot of this kind of work, then it might be worth investing in a hot air rework station.

Using a hot air rework station can be beneficial because it provides precise control over the amount of heat applied to the PCB. This helps ensure that components are removed and replaced safely without damaging other components or the board itself. It also allows you to work quickly and accurately so that your project can be completed efficiently.

Ultimately, whether or not you need a hot air rework station depends on the type of projects you plan to undertake. If your projects involve frequent removal and replacement of components on PCBs, then it would likely be beneficial to invest in one.

Final Words

The best hot air rework station is the one that meets your needs and budget. There are many factors to consider when choosing a hot air rework station, but the most important thing is to find one that suits your specific needs. With so many options on the market, there is sure to be a hot air rework station that is perfect for you.