While it is possible to solder silver with a soldering iron, it is not recommended. This is because silver has a very high melting point and is therefore very delicate.

What Is Silver Solder?

Silver solder is an alloy of silver and other metals, typically copper, zinc, or tin, that is used for joining silver pieces. The alloys have melting points below those of pure silver, so they can be used to join silver without melting the base metal. Silver solders are also used for joining other metals, including gold and platinum.

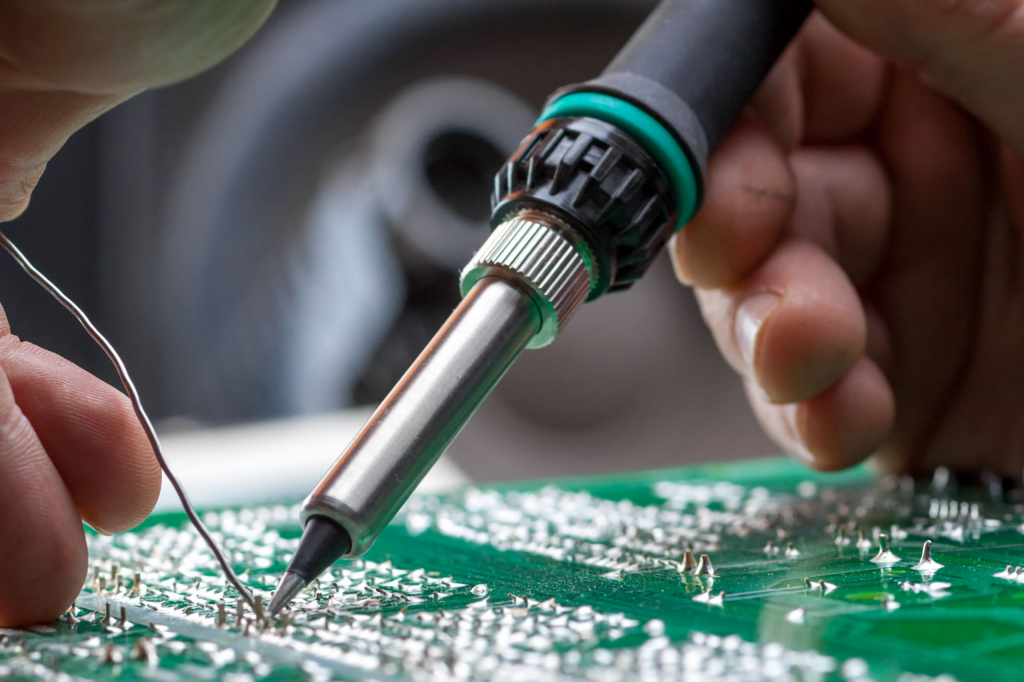

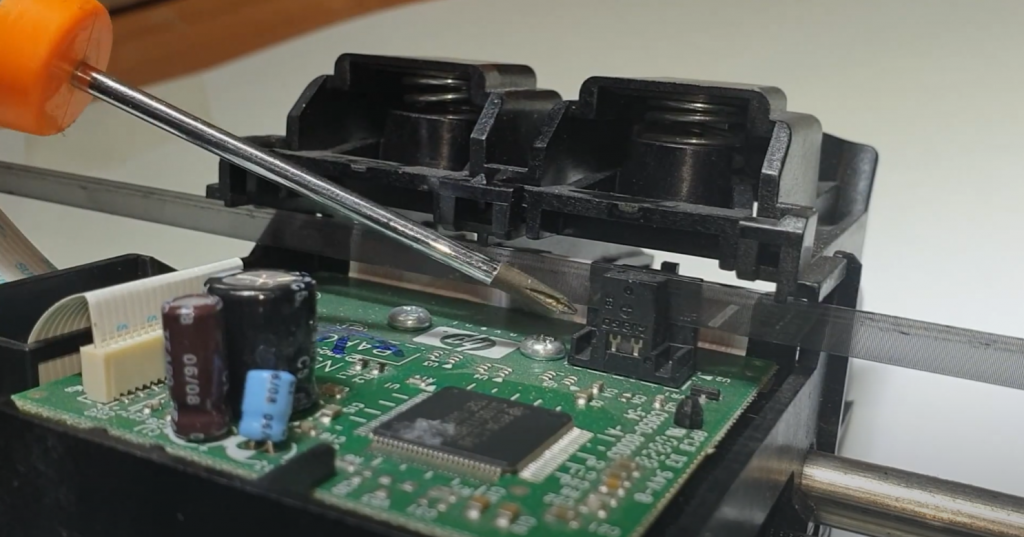

What Is a Soldering Iron?

A soldering iron is a handheld tool that heats up and applies melted metal (solder) to two surfaces in order to join them together. It’s a very useful tool for a variety of DIY projects, from electronics repairs to jewelry making.

When shopping for a soldering iron, you’ll want to consider the following factors:

- Wattage: This indicates how much power the element will receive and, as a result, how hot it will get. If you’re working with delicate electronics, you’ll want a lower wattage so you don’t damage the components. For heavy-duty jobs like welding, on the other hand, you’ll need a higher wattage.

- Heating time: This is how long it will take for the element to reach its maximum temperature. If you need to get started on your project quickly, look for an iron with a fast heating time.

- Tip type and size: The tip is the part of the iron that actually touches the surfaces you’re trying to solder. There are many different types of tips available, so choose one that is appropriate for your project. The size of the tip is also important – if it’s too large or too small, it won’t work well.

- Cord type: Some soldering irons have a cord that plugs into an outlet, while others have a cord that plugs into an extension cord or power strip. If you plan on using your iron in different locations, look for an model with a long cord or one that comes with an extension cord.

Advantages of Silver Solder

The main advantage of silver solder is that it has a high melting point, which means that it can be used to join pieces of metal together quickly and easily. Silver solder is also very strong and durable, making it an ideal choice for use in jewelry and other delicate applications.

Disadvantages of Silver Solder

While silver solder has many advantages, there are a few disadvantages to consider as well. One is that it is more expensive than other types of solder. Another is that it requires higher temperatures to melt, which can be a challenge for soldering iron tips. Finally, silver solder can be softer than other solders, making it more difficult to create clean, strong seams.

FAQ

What is the difference between silver solder and regular solder?

The main difference between silver solder and regular solder is the composition of the alloy. Silver solder contains a higher percentage of silver, which makes it more expensive than regular solder. Silver solder also has a higher melting point, so it can be used for soldering metals that require a higher temperature.

Do you need flux to solder silver?

Yes, you need flux to solder silver. Flux helps to prevent oxidation and allows the solder to flow smoothly.

Is silver solder pure silver?

No, silver solder is not pure silver. It is an alloy of silver and other metals, typically copper or zinc.

What kind of solder do you use for sterling silver?

For sterling silver, you’ll want to use a solder that has a high melting point. This will help to prevent damage to the silver. A good choice would be a silver-based solder.

What kind of flux do I need for silver solder?

For silver solder, you’ll need a borax-based flux. This will help to prevent oxidation and ensure a strong bond.

What are the 3 forms of silver solder?

The three forms of silver solder are hard, medium and easy. Each form has its own advantages and disadvantages, so it is important to choose the right one for the job at hand. Hard silver solder is great for high-strength applications, while medium and easy silver solder are better suited for applications where a softer joint is desired.

What temperature do you solder silver?

The melting point of silver is 1761 degrees Fahrenheit. When soldering silver, you will need to heat it up to this temperature in order to melt the metal and create a strong joint.

What percentage of silver is in silver solder?

The percentage of silver in silver solder varies depending on the type of silver solder being used. The most common type of silver solder contains approximately 65% silver.

What is silver solder good for?

It is used for bonding copper pipe and other metals together. Silver solder has a lower melting point than copper, so it can be used to join copper without melting the base metal.

Is silver solder toxic?

Yes, silver solder is toxic. The fumes from silver solder can be harmful if inhaled, and the solder itself can be harmful if ingested.

Related Video: Secrets to Perfect Silver Soldering

Conclusion

It is possible to solder silver with a soldering iron, although it may be difficult to get a good result. Silver is a soft metal, so it will require a very hot iron and a lot of patience. If you’re not careful, you could easily end up with a messy, uneven joint.