That eye-catching green hue isn’t just for looks. The green color of motherboards serves essential functions beyond aesthetic appeal. There’s a solid reason behind the ubiquitous emerald tint of computer motherboards. While black circuit boards may look sleek, the green PCBs found in most PCs provide vital benefits. The component-packed interior of your computer is brought to life by the green motherboard, but why this specific color? As it turns out, green offers key advantages for PCBs over other options. There are practical motives behind the prevalence of green motherboards beyond merely looking cool. The explanations may surprise you and change how you view this taken-for-granted computer component.

In a Nutshell

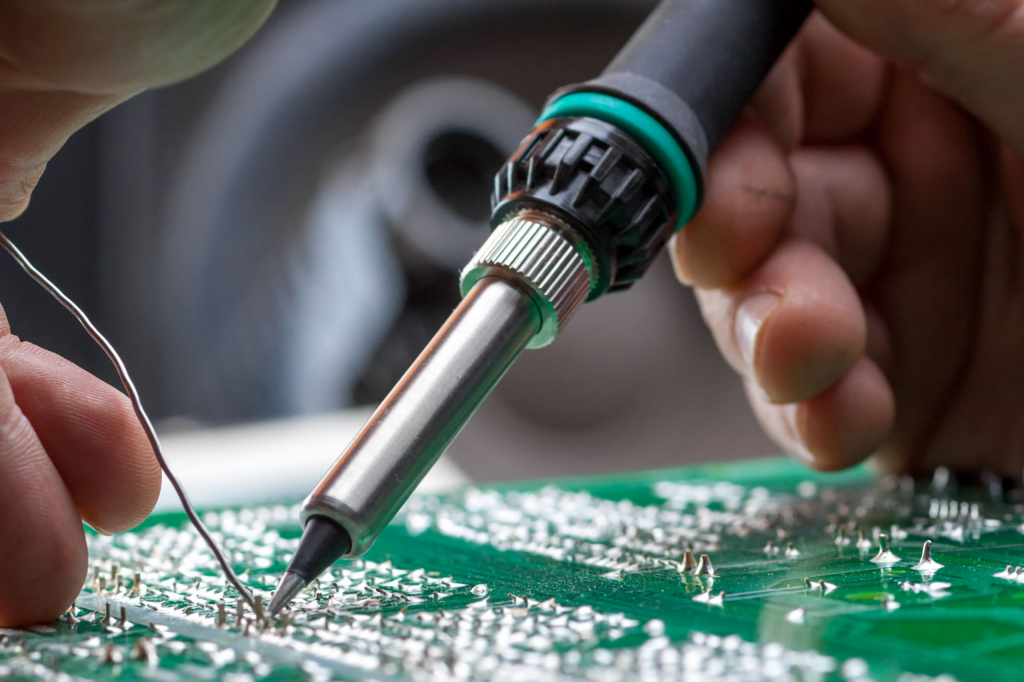

The green color of motherboards primarily comes from the solder mask coating applied to the PCBs. Solder masks serve important functions like preventing solder bridges between pads and protecting copper traces from corrosion. Most solder masks use green epoxy ink because it contrasts the shiny metallic solder and components against the dull green background. This helps automated optical inspection systems detect assembly issues like missing parts or poor solder joints. While other solder mask colors are sometimes used, green became the electronics industry standard many decades ago. The color also provides a unique yet neutral background that doesn’t distract from intricate PCB design patterns.

History of Motherboards

The motherboard is one of the most important components of a computer. It holds and connects all the crucial pieces of hardware, allowing the different parts to communicate and work together. The design and capabilities of motherboards have changed dramatically over the decades, closely following the rapid technological advancements in computing.

In the earliest electronic computers of the 1940s, the wiring between components was point-to-point, meaning each component was wired individually. There was no separate printed circuit board. The first true predecessor of the motherboard was introduced in the late 1950s with the SAGE air defense system, which had modular, removable sections holding components together.

The Birth of Motherboards – 1960s and 70s

In the 1960s and 70s, the first single-printed circuit boards that could be called “motherboards” emerged. These were minimal, connecting the CPU, memory, and I/O channels.

With the introduction of the Intel 4004 chip in 1971, motherboards could be mass-produced for personal computers. The Apple I, released in 1976, was one of the first true personal computers to contain a motherboard. It was designed by Steve Wozniak and consisted of only a few large ICs on a single board.

These early motherboards were generally one color – green, due to the resin used in their fabrication. They had far fewer layers and connections than modern boards. As more computing components were added throughout the 1970s, the boards became larger and more complex.

The PC Revolution – 1980s and 90s

The 1980s brought an explosion in home computing. With this came great leaps in motherboard technology.

IBM released its first PC in 1981, setting the standard form factor size for motherboards that are still used today – commonly called ATX. Competition drove companies to produce high-performance motherboards at lower costs. The boards grew more robust, with technology like RAM slots, integrated graphics, and dedicated sound cards.

Motherboard color expanded beyond green to shades like purple and brown during this period. More metal layers allowed tracks to cross over each other instead of running parallel, enabling more compact board designs.

In 1995, Intel’s release of the PCI bus led to widespread adoption of this standard expansion interface. Motherboards could now integrate peripherals like sound, video, and networking cards.

Modern Motherboards – 2000s to today

Today’s motherboards boast incredibly sophisticated and powerful computing capabilities. Here are some of the key innovations:

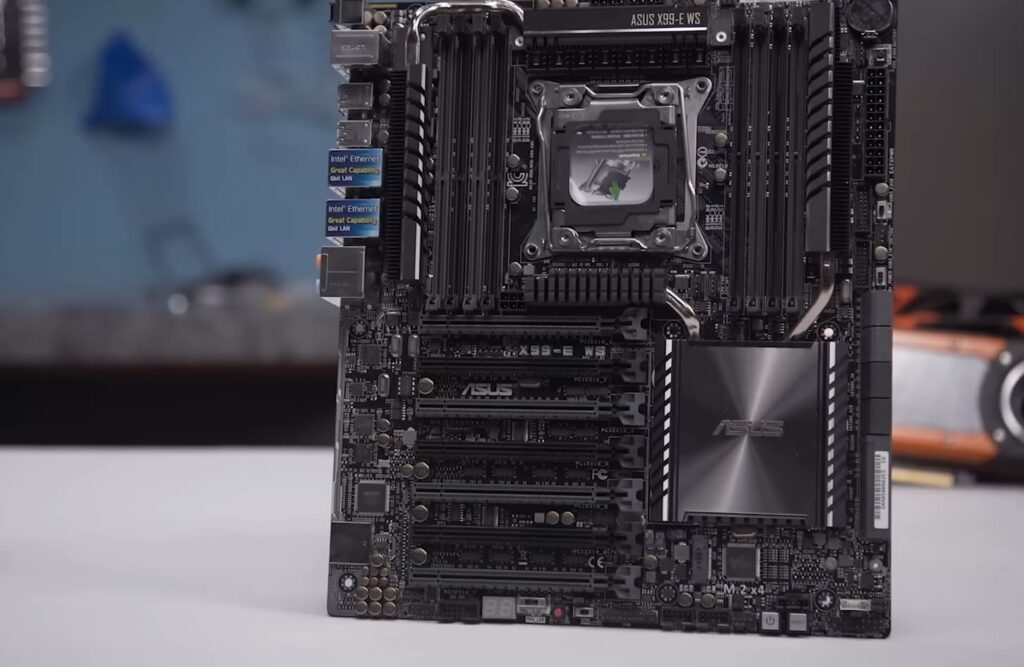

- Multi-core CPU support – Modern motherboards have CPU sockets and chipsets designed for multi-core desktop processors from Intel and AMD. Where early motherboards ran CPUs with only one core, today’s support CPUs with up to 18 cores.

- High-speed RAM – Motherboards now have DIMM slots supporting fast types like DDR3 and DDR4 RAM running at speeds over 3,000MHz. They utilize dual or triple-channel memory for more bandwidth.

- PCI Express – The PCI Express interface provides much faster expansion capabilities, with a high lane count allowing multiple video cards to be used together for immense graphics processing power.

- Onboard components – Features like integrated ethernet, audio, and USB that once required separate expansion cards are now built right onto the motherboard itself.

- Extensive cooling – With CPUs generating much heat under load, high-end motherboards have elaborate cooling solutions like fan headers and liquid cooling pumps to keep temperatures down.

Motherboard colors today can span the entire rainbow, with red, blue, and yellow being popular current shades. This allows PC builders to customize their system’s theme and style. The evolution continues as motherboard technology improves in tandem with cutting-edge computing components.

Composition of Motherboards

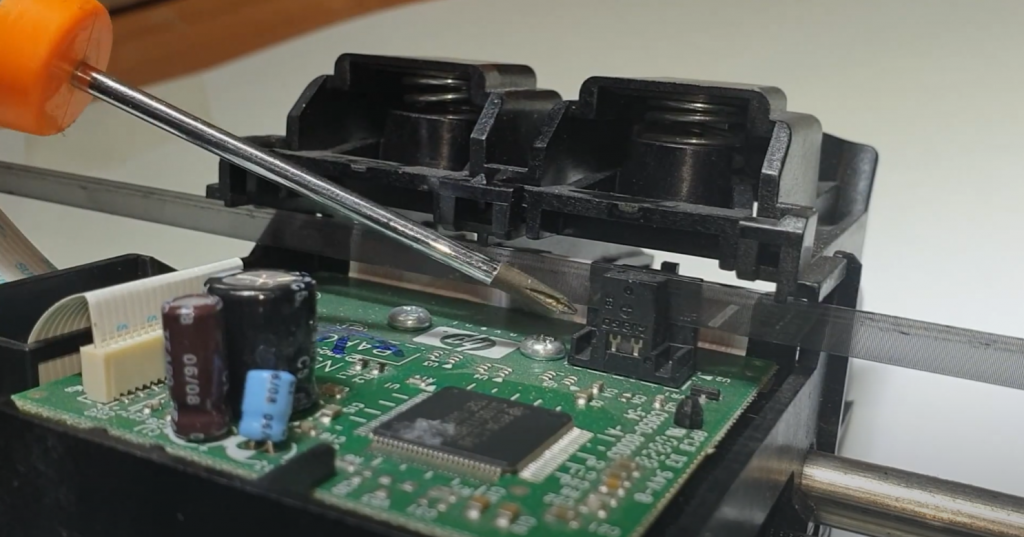

The motherboard is the backbone of a computer system, allowing all the separate components to communicate and operate together. Motherboards come in many shapes and sizes, but all contain common key parts that work together to make computing possible.

The motherboard provides the foundation on which the CPU, memory, expansion cards, storage drives, and other pieces can be installed to assemble a complete working system. The central printed circuit board (PCB) ties everything together through electrical pathways etched from materials like copper.

Printed Circuit Board

The PCB is the base of the motherboard, made from insulating layers like fiberglass and coated with conductive copper foil. The foil is etched to form the tracks for signals to traverse between endpoints. Vias or plated-through holes connect traces between layers.

More layers allow higher-density interconnected pathways since traces can cross over each other across layers. High-end boards may have up to 12 or more layers packed together.

Chipset

The chipset acts as the nerve center of the motherboard, controlling data flow between the CPU, memory, and peripheral devices. It traditionally contains a northbridge and a southbridge chip.

The northbridge links the CPU to high-speed components like RAM and expansion slots. The Southbridge handles peripherals through slower interconnects like USB, SATA, and audio. In newer boards, the functions are often combined into one chipset.

CPU Socket

The CPU socket provides the electrical interface between the processor and the rest of the system. It consists of metal pins and contact pads that align with the CPU to transfer power and data.

Popular sockets over the years include LGA775, LGA1151, PGA AM2, and PGA AM4 for Intel and AMD chips. The socket dictates CPU compatibility for the motherboard.

Memory Slots

Memory slots house the system RAM like DDR3 or DDR4 modules. They are connected directly to the processor to provide fast access to temporary data while the computer is running. The number and type of slots varies.

Common configurations include two or four DIMM slots for desktops or SO-DIMM slots for laptops. More slots allow for the installation of more RAM to improve performance.

Expansion Slots

Expansion slots permit adding specialty cards like graphics cards, RAID controllers, and NICs to enhance the system’s capabilities. Standard slots include PCIe x16, PCIe x1, and PCI.

Newer NVMe M.2 slots can accommodate super-fast solid-state drives. Multiple PCIe x16 slots support multi-GPU setups for demanding applications.

I/O Panel

The rear I/O panel provides external connectivity through an array of integrated ports. These include USB 2.0, USB 3.0, video outputs like HDMI, sound jacks, and LAN ports.

Higher-end boards may have additional connectivity options like USB Type-C or Thunderbolt 3 for ultra-fast file transfers and external storage.

Form Factor

The motherboard form factor defines its physical dimensions. ATX, Micro ATX, Mini ITX for desktops, and custom laptop-specific form factors are common types.

ATX boards offer more expansion room, while Mini ITX boards are designed for compact configurations. Each has its set layout for components, ports, and slots.

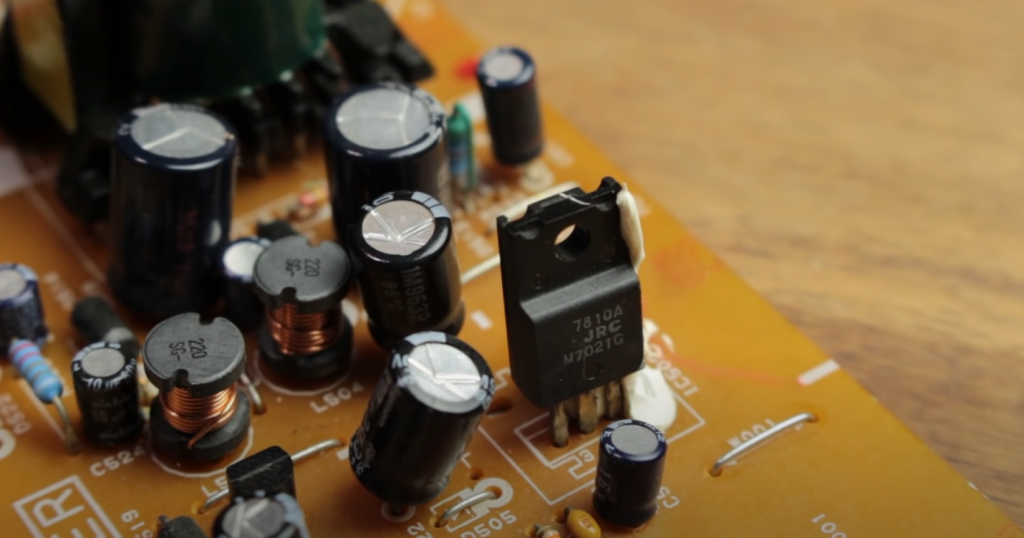

Power Circuitry

Voltage regulator modules, chokes, capacitors, and MOSFETs work together to take the main power supply input and generate stable voltages for the CPU, RAM, and other components. This allows them to run smoothly even under heavy loads.

Heatsinks help dissipate heat from the regulators and chipset. Fan headers power system cooling fans based on temperature. All of these crucial pieces fit together on the PCB to enable a fully functional computing platform via the motherboard.

The Green Color of Motherboards

Open up a desktop computer, and one of the first things you’ll likely notice is the green-colored printed circuit board, known as the motherboard. This crucial computer component provides the foundation on which all other parts, like the CPU, RAM, and storage drives, are installed. But why is the motherboard predominately shaded with this verdant green hue?

The answer lies in the manufacturing process of the printed circuit board itself. The vibrant green shade is a byproduct of the materials used to make affordable, reliable motherboards on a mass scale.

PCB Composition

A PCB is constructed by laminating fiberglass and epoxy resin layers, which bond the layers into a circuit board substrate. Fiberglass, which provides rigidity, is colored white to yellowish.

The resin is typically colored green. This epoxy resin is also called the “solder mask” layer. It provides insulation around the conductive copper traces etched from the copper foil bonded to the substrate.

Why Green?

The green resin provides an opaque background, which offers good contrast against the copper traces. This allows for easier visual inspection of the PCB during manufacturing for defects or faults in the etched wiring paths.

The resin also gives the PCB a unique color for identification. Standardized green PCBs are easily recognizable versus other circuit board types. The green color is inherent to the insulating epoxy resin used in cost-effective PCB production.

Alternative PCB Colors

While standard green is the most common, PCBs can be made in other colors too:

- Blue – Often used for boards designed for higher voltage or high-frequency signals.

- Red – Sometimes used for power circuit boards in high-power electronics.

- Yellow – Some applications, like industrial control systems, need special identification.

- Black – Aesthetically pleasing and used by enthusiasts for custom PCB projects.

However, green remains the color of choice for the mass production of affordable commercial PCBs in computers and other electronics.

So, when you look at a desktop computer’s motherboard, the omnipresent green color is directly tied to the printed circuit board’s materials. While it may seem dull compared to other colors, the green helps impart quality and reliability to this vital component.

FAQs

Why Do Many Computer Motherboards Have a Green PCB?

Many modern computer motherboards feature green printed circuit boards (PCBs). There are a few key reasons why green has become a very popular color for motherboard PCBs:

- Cost – Green solder mask is one of the most affordable solder mask colors for PCB production. Going with an inexpensive solder mask helps keep motherboard costs down.

- Aesthetics – The green color has become associated with high-tech computer hardware over the years. Using green helps motherboards look more sophisticated and advanced. It’s an iconic color in the PC world.

- Functionality – The green color provides a good contrast with components and makes the circuits more visible. This helps inspect boards for quality control, repair/troubleshoot boards, and assemble components during manufacturing. Good contrast is useful.

Green is popular for motherboards because it’s inexpensive, looks high-tech, and offers great visibility of the circuits. While other colors like blue, red, yellow, or black are sometimes used, green has become the most common and expected color in motherboard manufacturing over the past few decades. For both practical and aesthetic reasons, expect most computer motherboards to keep featuring green PCBs for years to come.

Are There Other Colors Besides Green for Motherboards?

While green is by far the most popular color for motherboard-printed circuit boards (PCBs), you will occasionally see motherboards featuring other colors:

- Blue – Used to give a cool, futuristic look. Often seen on high-end gaming motherboards.

- Red – Used to give a fiery, high-performance look. Seen on some overclocking-oriented boards.

- Yellow – Gives an exotic, attention-grabbing look. Rare except on special editions.

- Black – Makes motherboards look elegantly high-tech. It is only seen on expensive boards due to the higher cost.

- White – Gives motherboards a clean, clinical look. Uncommon due to discoloration concerns.

- Gold – Very rare except for decorative heat sinks/covers. Provides an elite, premium luxury appearance.

While these alternate PCB colors occasionally appear, green still dominates the majority of consumer and business-oriented motherboards. Green offers the best balance of cost, aesthetics, visibility, and performance. It has become the motherboard industry standard. For most computer builders, you can expect to see many iconic green motherboards for many years.

Related Video: Why Are Circuit Boards Green?

Final Thoughts

While black or other colored circuit boards may look sleek, the ubiquitous green hue of motherboards is there for good reason. The solder mask coating gives them the iconic green shade that has become standard for PCBs. The dull matte finish provides excellent contrast against metallic components and solder joints, enabling automated optical inspection. Green also gives a neutral background that lets complex PCB trace layouts take center stage visually. So next time you crack open a computer and see a green motherboard, know that the color is not just for show. The green tint serves practical purposes to support manufacturing and enhance board aesthetics through function.