The shift from leaded solders to lead-free formulations was a major change for electronics assembly and production. But what exactly replaced the lead in modern soldiers? When restrictive laws kicked the electronics industry’s lead habit for environmental and health reasons, manufacturers had to reinvent solder with safer alternatives. Various metals stepped in to substitute for lead’s unique properties in molten solder alloys. Tin and ingredients like silver, copper, bismuth, and zinc now dominate the makeup of lead-free solder. Blending these and other elements creates lead-free solders with tradeoffs across characteristics like melting point, joint strength, and conductivity. Let’s explore the metallic ingredients that went into engineering new lead-free solder formulations.

Executive Summary

Modern lead-free solder removes the lead of traditional solder and replaces it with other metals to maintain properties like melt flow and joint strength. The primary constituent is tin, usually comprising over 90% of lead-free formulas. Silver is added around 3% to stabilize tin against whiskering. Copper at 0.5-2% strengthens joints and improves thermal transfer. For low-temperature applications, bismuth and indium help lower melting points. Trace antimony or zinc enhances solder flow. The exact blend of these and other substitute metals is carefully engineered for different solder needs. But tin forms the main building block of lead-free solder, providing the strong backbone required once hazardous lead gets banned.

Composition of Lead-Free Solder

Effective lead-free solder requires carefully blending various metals to achieve desired characteristics when molten and solidified into electrical joints. The core ingredients of most lead-free solder impart distinct properties that combine to produce a high-performance bonding alloy without hazardous lead.

Tin as the Cornerstone

The most essential constituent of nearly all lead-free solder formulations is tin, comprising over 90% of typical blends. Tin possesses a unique mix of metallurgical traits that make it the ideal backbone for lead-free solder:

- A relatively low melting point of 232°C enables practical soldering temperatures.

- Strong malleability when solid provides durability under thermal and mechanical stresses.

- Corrosion resistance ensures the longevity of soldered connections.

- The ability to readily alloy with various metals allows tailoring solder behavior.

- Smooth molten flow facilitates wetting and adherence to component leads during soldering.

No other abundant and affordable metal combines all these desirable attributes. The prevalence of tin across electronics soldering applications decreased with the advent of lead-based solders centuries ago. But tin resurged as the foundational element of modern lead-free solder technology with the elimination of lead due to toxicity.

Silver’s Anti-Whiskering Effect

While costly, a 2-4% addition of silver is incorporated into most lead-free solder alloys to reap several benefits:

- Stifles whisker growth – tin is prone to growing tin whiskers, conductive crystalline structures that can pierce the insulation and cause electrical shorts, a phenomenon silver prevents.

- Enhances fatigue cycle resistance – silver increases lead-free solder’s durability and lifetime under mechanical and thermal stresses.

- Improves solderability – Silver enables superior wetting capabilities during the soldering process for smooth flow and adherence.

- Offsets tin pest conversion – high purity tin above 13°C is subject to slowly deteriorating into a brittle grey powder non-conductive allotrope over months, a reaction silver counteracts.

- Slightly hardens the alloy while contributing ductility in small amounts.

Silver provides numerous irreplaceable enhancements to tin-based solders despite its high price, making it a standard ingredient.

Copper for Added Strength

Copper is frequently incorporated into lead-free solder formulations at 0.5-2% to impart several helpful traits:

- Hardens the alloy, increasing the shear and tensile strength of solidified solder joints while reducing creep under sustained loads.

- Widens the plastic range of solder for increased fatigue life and durability.

- Improves thermal transfer through soldered connections, which must endure temperature swings.

- Enhances electrical and thermal conductivity through joints.

Too much copper risks compromising ductility and wetting capability. But in small calibrated amounts, copper significantly bolsters the robustness of lead-free solder.

Bismuth Lowers Melting Range

Where low-temperature soldering is essential, bismuth at 1-3% is added to tin-silver or tin-silver-copper lead-free solder:

- Melts at 271°C, far below tin’s 232°C melting point, reducing soldering temperatures.

- Allows attachment of delicate components vulnerable to heat damage during normal soldering.

- It can decrease solid solder joint flexibility and strength at higher operating temperatures.

- It must be carefully balanced with silver and copper to avoid brittleness.

Bismuth facilitates niche applications like glass-to-metal seals and step-soldering temperature-sensitive electronics with a critical low melting range.

Trace Elements’ Precision Adjustments

While tin, silver, and copper constitute the majority of typical lead-free solder, additional minority constituents getting added at under 1% provide fine-tuned metallurgical effects:

- Antimony enhances solder flow traits and acts as a strengthening agent.

- Germanium improves wetting on copper surfaces.

- Nickel prevents destructive tin pest reactions in the high-purity tin.

- Zinc reduces dross formation while lowering surface tension.

- Titanium stabilizes the grain structure for increased thermal fatigue resistance.

These supplemental metals allow exact dialing in characteristics like wetting behavior, fluidity, joint hardness, creep resistance, tensile strength, shelf life, and microstructure. Even minute-optimized additions of specialty ingredients can yield substantial performance benefits tailored to demanding applications.

Advantages and Disadvantages of Lead-Free Solder

Lead-free solder rose to prominence as an alternative to conventional tin-lead solder, offering benefits but also some challenges compared to lead-containing formulas.

The shift to lead-free solder aimed to eliminate lead due to its toxicity and environmental impacts. However, the change affected soldering processes, joint reliability, and costs. As lead-free solder continues evolving, many initial drawbacks are mitigated through improved alloys.

Reduced Toxicity and Environmental Impact

The chief advantage of lead-free solder is removing hazardous lead and its health consequences from electronics manufacturing. Lead accumulates in bodies and the environment. Lead-free solder avoids these issues, providing a more sustainable and safer material. Many regions enacted regulations to spur its adoption by electronics companies based on lead risks.

Higher Melting and Processing Temperatures

Common lead-free solders have melting points around 217-220°C versus 183°C for leaded solder. This subjects components to higher temperatures during soldering, risking damage to delicate parts. It also slows production and increases energy usage. Some low-temp lead-free solders address this.

Potential Thermal Fatigue Susceptibility

Thermal cycling can cause earlier failure in some lead-free alloy joints. Lead-added ductility, while lead-free solders are often more brittle, leading to cracking under repeated expansion and contraction stresses. Careful alloying balances hardness with malleability to improve durability.

Legacy Component Compatibility Challenges

Many older components were only designed for lead-containing solders. Lead-free solders can degrade incompatible plastics or fail to wet aged platings not formulated for newer alloys. Backward compatibility remains a consideration.

While overcoming lead toxicity, initial lead-free solders posed some new challenges. But enhancements continue to optimize performance, making lead-free solder a standard in modern electronics assembly.

Applications of Lead-Free Solder

Lead-free solder has become widely adopted across electronics manufacturing industries, including consumer products, automotive, aerospace, and medical devices. Its reduced toxicity and environmental impact make it essential for many applications today.

Consumer Electronics

Lead-free solder is now standard for assembling consumer electronics like phones, computers, and home appliances. These are produced in huge volumes, amplifying any health or environmental risks from lead. Consumer safety regulations in regions like Europe and Asia spurred tech companies to implement lead-free processes and components. It helps mitigate risks of lead leaching into landfills as electronics get discarded.

Automotive Manufacturing

Vehicles contain vast amounts of electronics needing reliable soldering. The long lifespan of cars also amplifies lead’s potential to accumulate. Automakers thus transitioned to lead-free solder to meet environmental standards. Some mission-critical high-temperature automotive systems still rely on leaded solder, but new low-temp lead-free alloys aim to displace the remaining niche uses of lead.

Aerospace and Defense

Although aerospace still uses leaded solder in certain sensitive applications, the industry continues moving to lead-free solder. Tin whiskering problems caused earlier hesitation, but mitigations now exist. Aerospace seeks environmental benefits and avoids lead contamination across long equipment lifetimes. Lead-free solder also reduces the risks of tin-lead coatings clogging coolant pipes in aircraft.

Medical Devices

Medical device producers have embraced lead-free solder to increase patient product safety by eliminating lead exposure, especially for implanted products. The higher temperatures of lead-free solder posed challenges for sensitive electronics, but new alloys addressed this. Lead contamination also threatened sterilization processes. Lead-free biocompatible solders are now available for medical devices.

Reliable lead-free soldering processes developed across industries ensure the beneficial removal of lead while maintaining product quality and consumer safety.

Alternatives to Lead-Free Solder

Due to regulatory restrictions and health concerns over lead content, lead-free solder has become the preferred solder type for many electronics applications. However, lead-free solder has some disadvantages compared to traditional tin-lead solder, including higher melting points, poorer wetting, and potential issues with tin whiskers. For applications where lead-free solder may not be suitable, viable alternatives exist.

Flux

Flux serves an important function in soldering by removing oxides and preventing re-oxidation of the metal surfaces to be joined. While flux is an essential companion to solder, flux can also enable solder-free connections in some situations. Flux formulations designed for no-clean applications can remain inert after soldering and maintain a small conductive path between components.

The properties of no-clean flux make it suitable for low-power connections that do not require high conductivity. Applications such as bonding connectors, jumper wires, and links on printed circuit boards can often utilize flux alone without solder. The flux conduction path has higher resistance than a solder joint but can be sufficient for signals or power transmission in some circuits.

Flux conduction provides reduced joint complexity compared to soldering. The process only requires the application of flux between mating surfaces, eliminating the need for soldering irons, solder wire or paste, and cleaning. However, the connections may be less mechanically robust than soldered joints and more prone to disruption from vibration or impacts.

Conductive Adhesives

Conductive adhesives provide electrical connections by embedding conductive particles into an adhesive matrix. Common conductive particles include silver, copper, and nickel, while epoxy, silicone, and acrylic resins often form the binder.

Conductive adhesives can substitute for solder in applications such as surface mount assembly, component-to-board connections, and printed circuit board repairs. The adhesives cure much lower temperatures than solder melting points, permitting their use with temperature-sensitive components. Repairs with conductive adhesive avoid the risks of heat damage associated with soldering.

While conductive adhesives conduct electricity, their volume resistivity is higher than solders. Care must be taken to account for increased joint resistance in circuit design. The connections may also be more prone to failure under mechanical or vibration stresses versus soldered joints.

Conductive adhesives provide simpler processing than soldering. The application requires little equipment beyond dispensing the adhesive and providing heat or UV light for curing. The cured connections require no cleaning. Conductive adhesives also avoid solder hazards like splattering, fumes, and flux residues.

FAQ

How does silver modify the properties of tin-based lead-free solder?

Silver is added at around 2-4% into most lead-free solder alloys containing tin. Though costly, silver provides several vital benefits:

- Prevents tin whisker growth – tin is prone to growing conductive crystalline whiskers, which can cause shorts, a problem silver alleviates.

- Increases fatigue resistance – silver improves lead-free solder’s durability under mechanical and thermal stresses to avoid joint failure.

- Enhances solderability – Silver enables solder to wet and flow onto surfaces more effectively during soldering.

- Offsets tin pest – high tin solders risk conversion to a powdery, non-conductive allotrope; silver blend counters this.

- Hardens the alloy – silver strengthens the lead-free solder and raises melting temperature slightly.

Silver’s measurable improvements to tin-based solder make its added cost worthwhile for electronics manufacturers. The tin-silver alloy duo forms an ideal backbone for reliable lead-free solder.

How do bismuth and indium reduce the melting point of lead-free solder?

For applications where low soldering temperatures are essential, specialized lead-free solders incorporate the low-melting metals bismuth and indium:

- Bismuth melts at 271°C and comprises 1-3% of low-temp lead-free solder. It acts as a mild reducing agent.

- Indium alloyed around 1% melts at 157°C. It readily oxidizes during soldering to aid flow.

- Bismuth and indium can decrease tin-silver solder melting points by over 50°C versus standard lead-free solder.

- Lowering melting temperature reduces heat stress on delicate electronic components during soldering.

- The tradeoff is slightly weakened joint strength and flexibility at higher temperatures.

Where low-temperature soldering is critical, a quaternary tin-silver-bismuth-indium alloy balances optimal melting range with acceptable mechanical properties once solidified into solder joints.

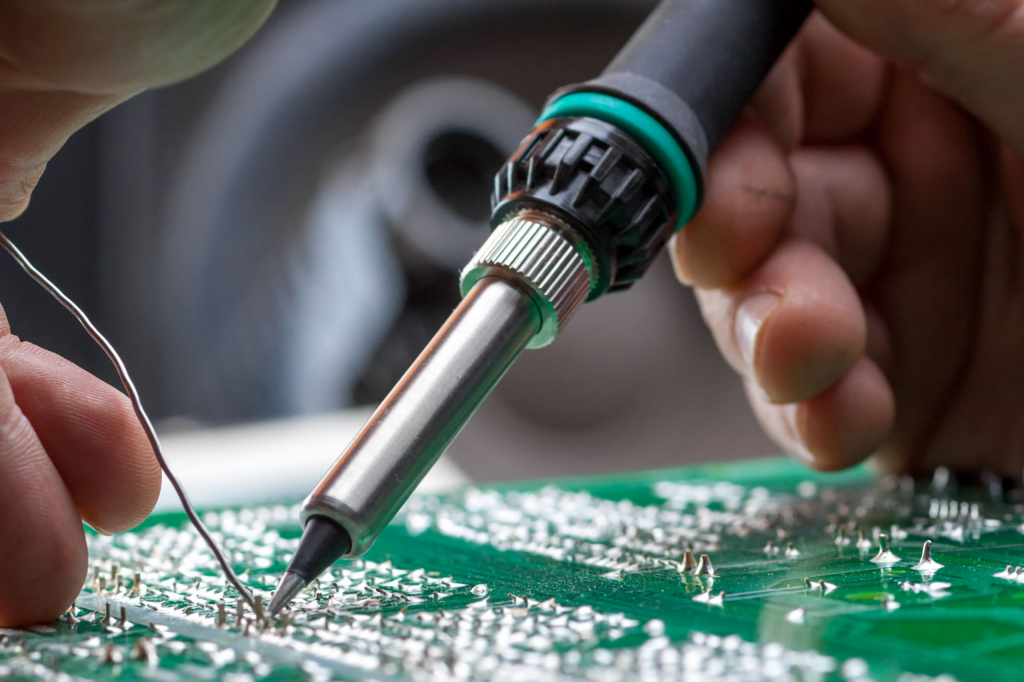

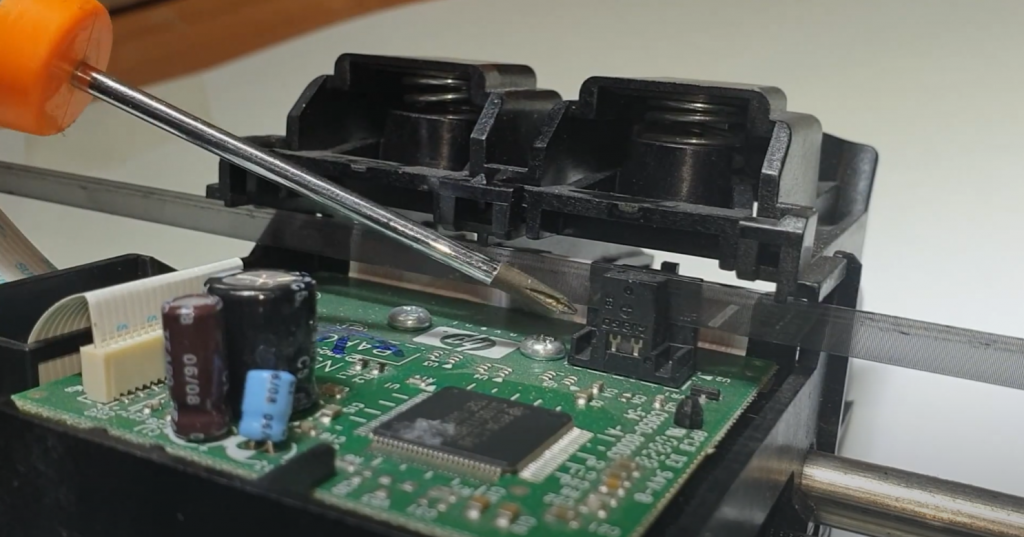

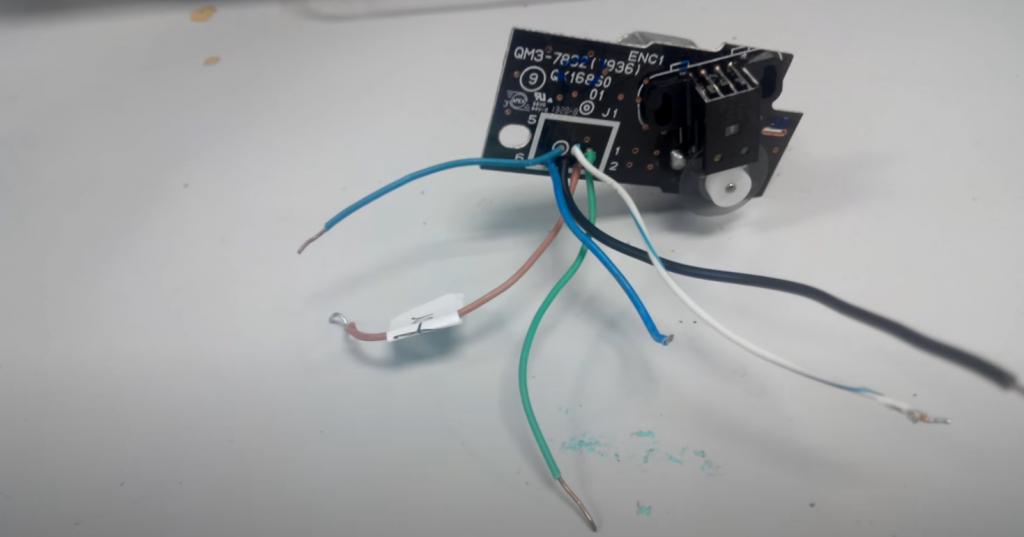

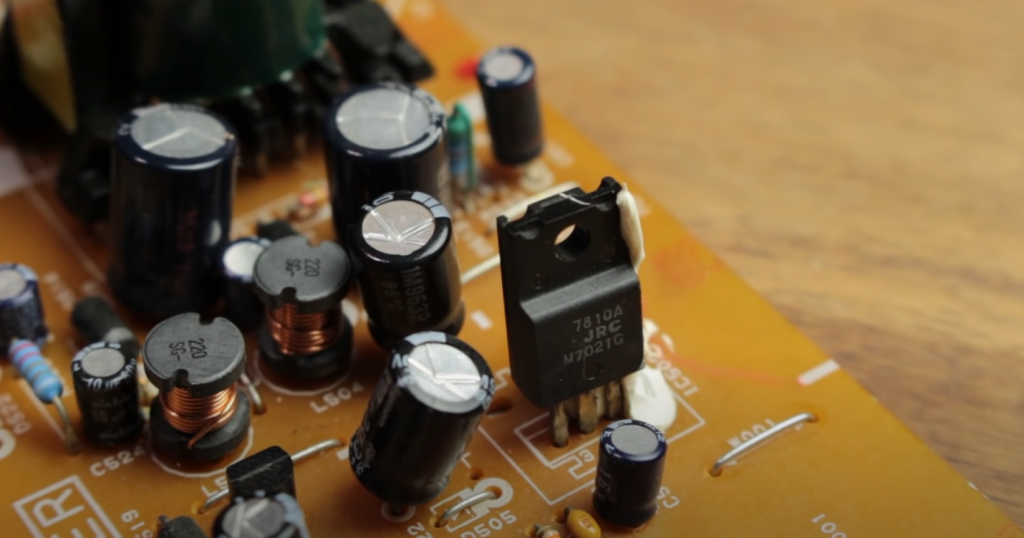

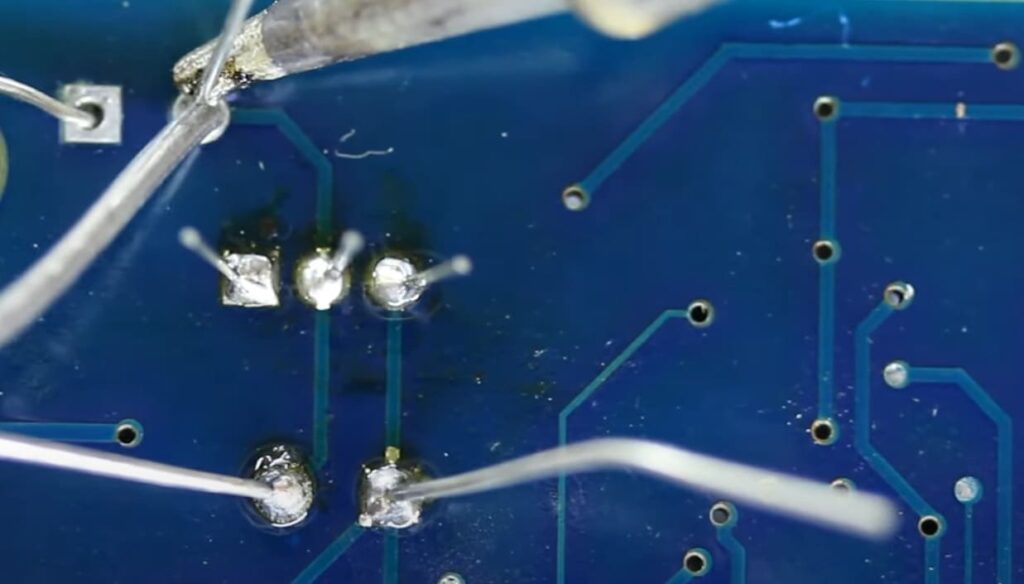

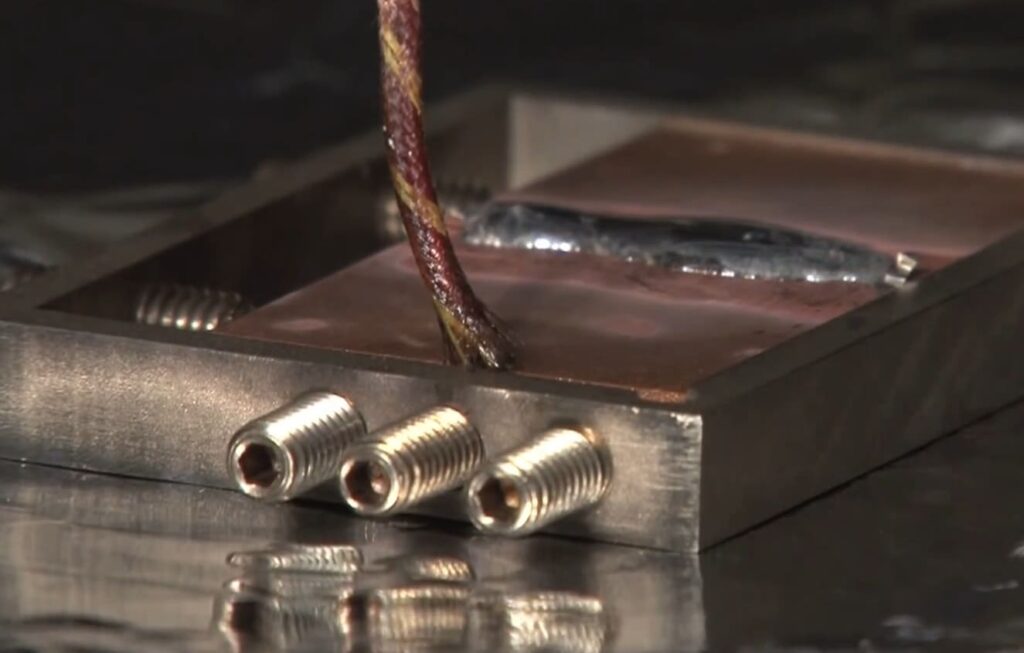

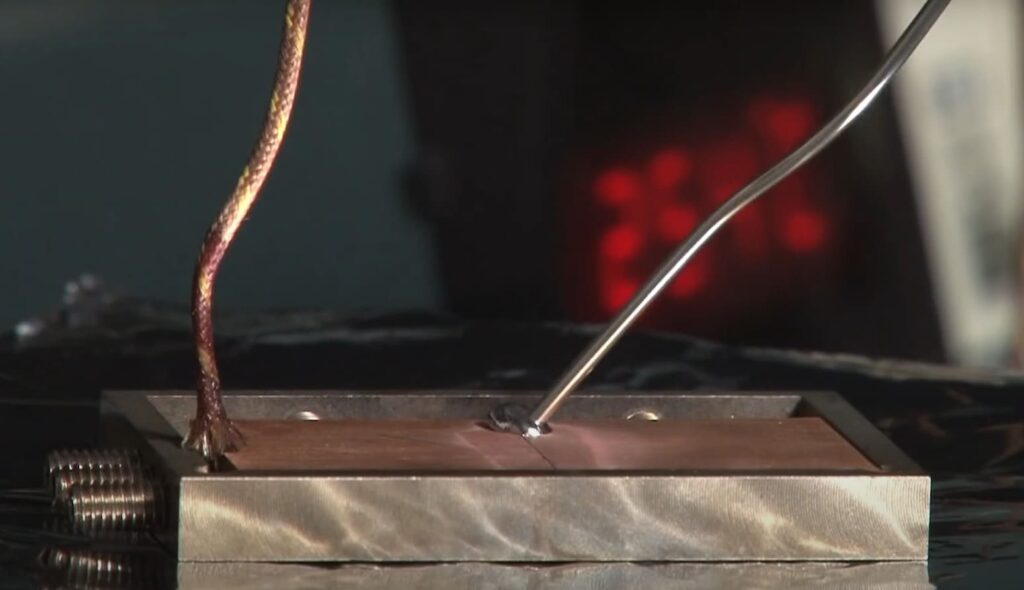

Related Video: Lead solder vs lead-free solder vs silver solder

Final Words

The transition from lead-based solders required finding alternative metals able to mimic lead’s useful properties. Modern lead-free solder relies primarily on tin, which comprises over 90% of most formulations. Added metals like silver aid solderability, copper strengthens joints, bismuth and indium reduce melting points for low-temp uses, and zinc or antimony improves flow characteristics. Precision blending of these substitute ingredients produces lead-free solder alloys with different traits optimized for various applications. While no single element perfectly replaces lead, combining tin with small amounts of other safe metals at exact ratios resulted in lead-free solder solutions that meet today’s demanding electronics assembly needs.