As technology advances, makers and engineers choose between programmable logic controllers (PLCs) and microcontroller platforms like Arduino for automation and control projects. Both offer digital programmability but have key differences that make each better suited for certain applications. When picking the right solution for your needs, it’s important to weigh factors like complexity, flexibility, cost, and ease of use. To help decide between PLC or Arduino, it’s valuable to understand the pros and cons of each. This guide will compare the critical differences between the two popular options and provide key questions to ask yourself when choosing the best fit for your next project.

Quick Glance Highlights

Both PLCs and Arduino have pros and cons depending on the application. PLCs are ideal for large industrial automation projects requiring robust I/O, reliability, and centralized control. They’re designed specifically for factory environments. Arduinos offer flexibility and customization for smaller projects, prototyping, and hobbyists. Their open-source nature makes Arduinos highly customizable with various add-on shields. PLCs may be preferable for complex professional applications, but Arduinos provide a simpler, cheaper option for small-scale projects or learning. Consider the size, budget, complexity, and technical expertise when choosing between PLC or Arduino for an automation, robotics, or control project.

What is a PLC?

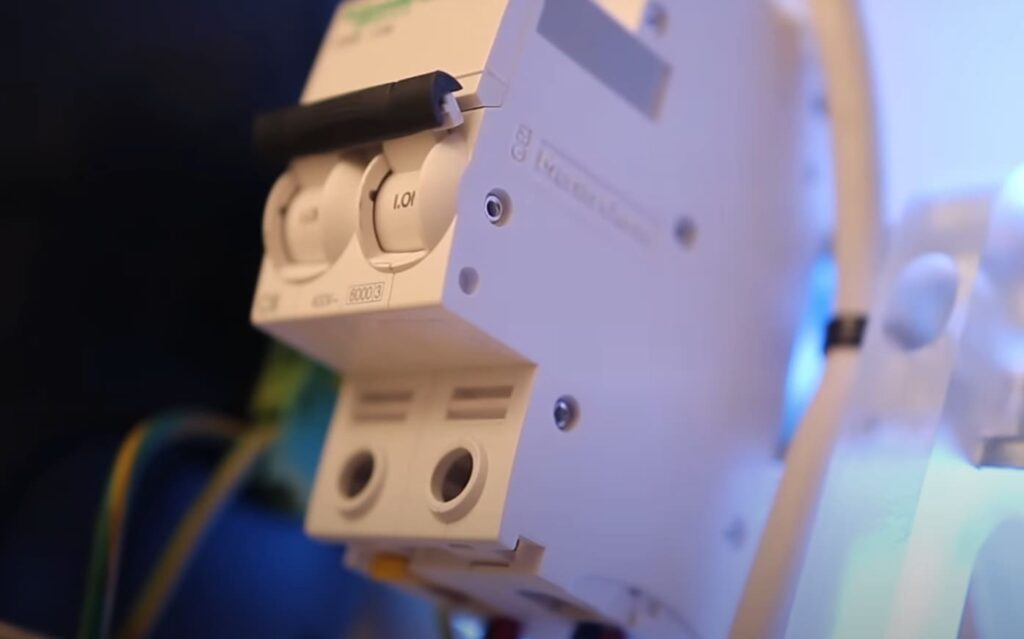

Programmable Logic Controllers (PLCs) are digital industrial computers that automate electromechanical processes in factories, plants, and machinery. PLCs control machines and processes through digital logic and solid-state relay circuits designed to replace older systems using timers, relays, and drum sequencers.

Definition and Explanation of PLC

A PLC is an industrial computer that has been ruggedized and adapted for controlling manufacturing processes such as assembly lines, robotic devices, or activities that require high reliability, ease of programming, and process fault diagnosis. PLCs contain a CPU, memory, input/output circuits, and a power supply. They are programmed using application software on personal computers and then installed to control machines and processes through digital and analog I/O modules wired to sensors and actuators.

Unlike general-purpose computers, the PLC has memory for the I/O state and ladder logic processing. PLCs sample inputs and outputs in real time to execute user programs written in ladder logic or another IEC 61131-3 language. They provide high-speed, deterministic, real-time control of outputs based on processing logic and scanning inputs. PLC systems are modularly expandable through the distributed I/O architecture.

Construction and Working Principles

The central processing unit (CPU) executes the PLC’s logic program and processes I/O. The CPU contains a microprocessor, RAM, ROM, and nonvolatile memory to store logic programs. Input interfaces convert field device signals from switches, sensors, etc., into logic signals for the CPU. Output interfaces convert CPU logic into signals that actuate switches, valves, drives, and other field devices through digital or analog outputs.

The power supply converts AC mains voltage to low DC voltage to power the CPU, I/O, and field devices. Modular or expansion I/O provides additional input and output capacity. The CPU follows a program execution cycle continuously: reading inputs, executing the logic program, and updating outputs.

Advantages of PLCs

- Reliable and robust for industrial environments

- Flexible programming allows changes in logic without rewiring

- Computational abilities for math, data processing, automation

- Communication compatibility with HMIs, SCADA, drives, and other control systems

- Scalable and modular I/O capabilities

- Remote monitoring and control through ethernet networks

- Built-in diagnostics capabilities to identify faults

Disadvantages of PLCs

- Higher cost than simpler control systems like relays

- Requires learning specialized programming language ladder logic

- Cybersecurity risks from networked connectivity

- Debugging/troubleshooting code can be complex

- Forced to follow a rigid program execution cycle less suited to non-deterministic processes

Applications of PLCs

PLCs are used extensively in industrial automation and process control across many industries, including:

- Manufacturing: For controlling machines, assembly lines, robotic arms, and automated processes.

- Energy: PLCs help automate and control power generation, transmission, and distribution.

- Oil and Gas: Used to control drilling rig equipment, pipeline flow, and refining processes.

- Chemical/Pharma: For batch control, mixing, sequences, and formulas.

- Water/Wastewater: PLCs control filtration, flow rates, and chemical treatment.

- Transportation: To automate guided vehicles in warehouses and control subway systems.

- Infrastructure: Large buildings’ HVAC, electrical, and water systems use PLCs.

PLCs provide reliable software control of electromechanical processes with moderate technical complexity across many sectors.

What is an Arduino?

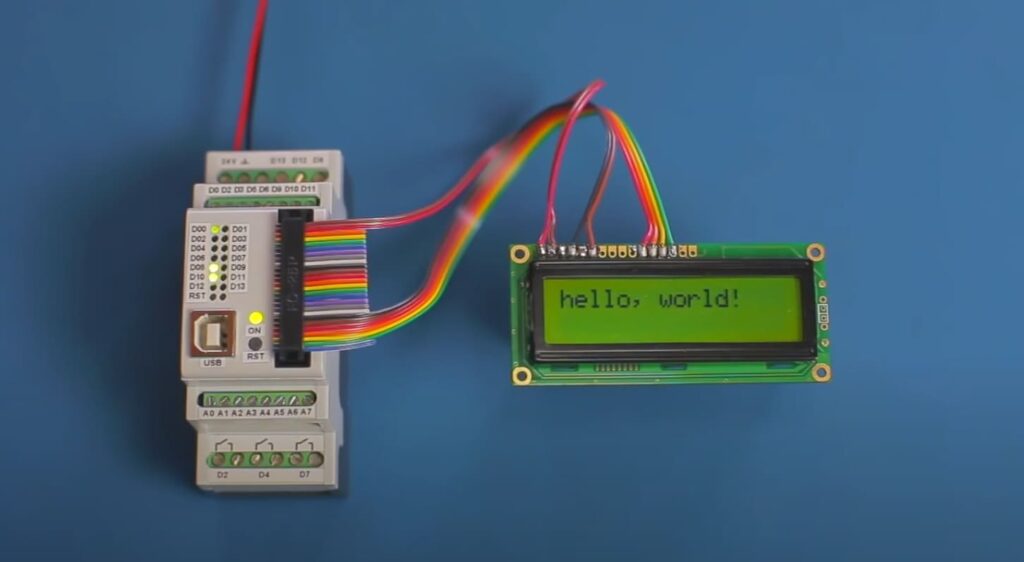

Arduino is an open-source electronics platform based on easy-to-use hardware and software. Arduino boards are microcontroller circuit boards that can be programmed to sense and control objects in the physical world.

Definition and Explanation of Arduino

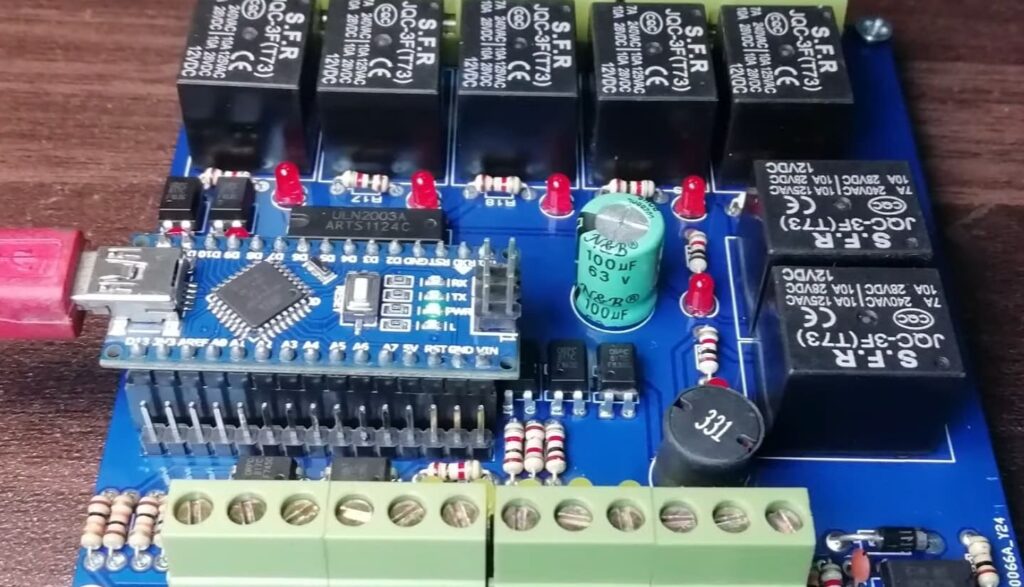

An Arduino is a small, inexpensive, programmable circuit board that can be used for building customizable electronic projects. At the heart of every Arduino board is an ATmega microcontroller chip. The board includes digital I/O pins to connect to sensors, motors, lights, and other peripherals. Arduinos can be powered through USB, battery, or AC power.

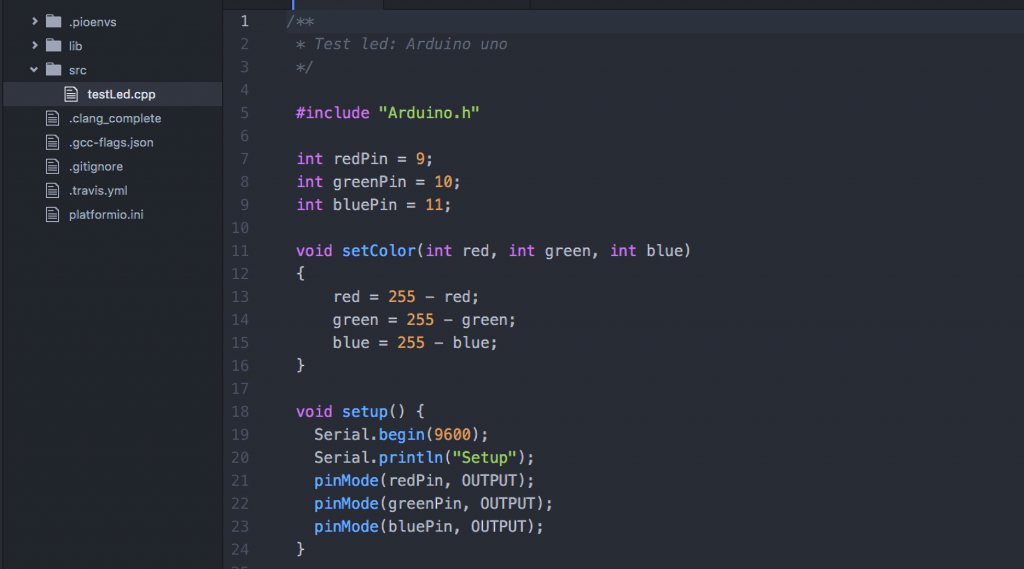

Arduino boards are programmed using the Arduino IDE (Integrated Development Environment) based on the C and C++ languages. This allows developers to write code that senses inputs from buttons, sensors, and other devices connected to the board and controls outputs like LEDs, motors, and displays. The simple Arduino IDE uses free downloadable software libraries to program the board without needing extensive hardware knowledge.

Over 40 different official Arduino boards are available, from small form-factor boards to Linux-powered boards. Each has varying microcontroller speed, memory, number of I/O pins, and capabilities. Arduino’s versatility, flexibility, and simplicity have made it the go-to platform for electronic prototyping, experimentation, and hobbyist projects. Universities also use Arduino boards for teaching electronics and programming fundamentals in an accessible way.

Construction and Working Principles

The main components of an Arduino board include:

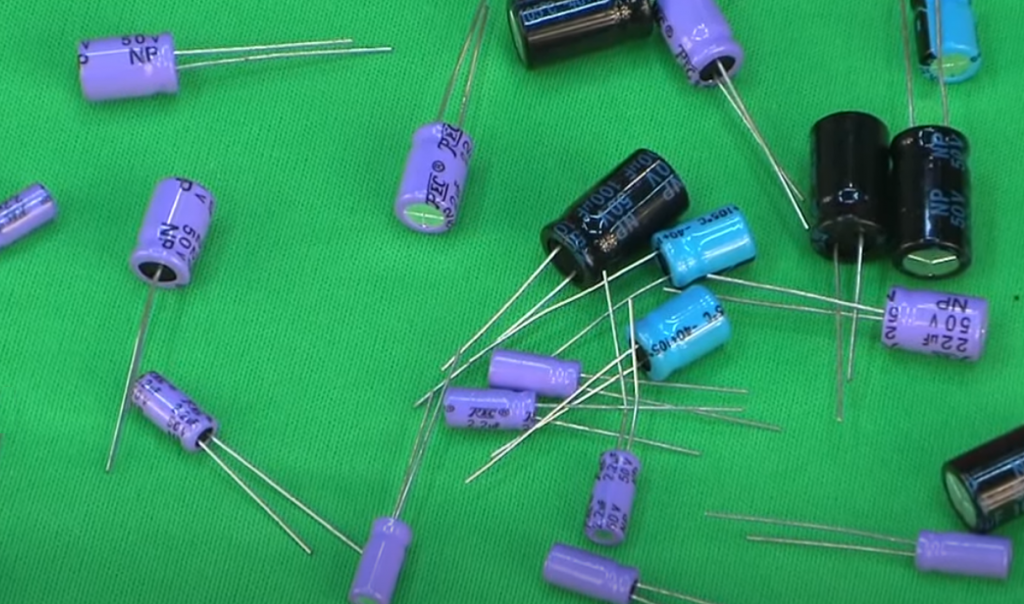

- Microcontroller: The brain of the board with the CPU, memory, and processing capabilities.

- Digital I/O Pins: Pins that connect to electronic circuits for sensing and controlling.

- USB Port: Allows uploading programs from a computer and also serves as a power source.

- Power Supply: Onboard power from USB, batteries, AC adapter, or solar panels.

- Crystal Oscillator: Provides clock signal to time and synchronize operations.

- Headers or Connectors: Socket the board into breadboards or connect to other circuit boards.

The ATmega microcontrollers commonly run at speeds of 16 or 32 MHz and have kilobytes of program memory. Arduino boards can either be powered through the USB port connected to a computer or separate external power from batteries or power supplies. Input voltage can range from 7-20V and is regulated down to the lower voltages needed.

Advantages of Arduino

- Inexpensive compared to other programmable boards

- Beginner-friendly Arduino IDE using C/C++

- Open-source hardware and software

- Cross-platform compatibility

- Extensive user community and resources

- Easily interfaces with diverse sensors, displays, and other components

- Available in many different board sizes and form factors

Disadvantages of Arduino

- Limited processing power on microcontrollers

- It is not as robust for harsh mechanical or outdoor use

- Typically used for simpler projects, not advanced industrial applications

- Debugging complex code can be challenging

- Some technical knowledge is needed compared to visual programming platforms

Applications of Arduino

Arduino boards are commonly used for:

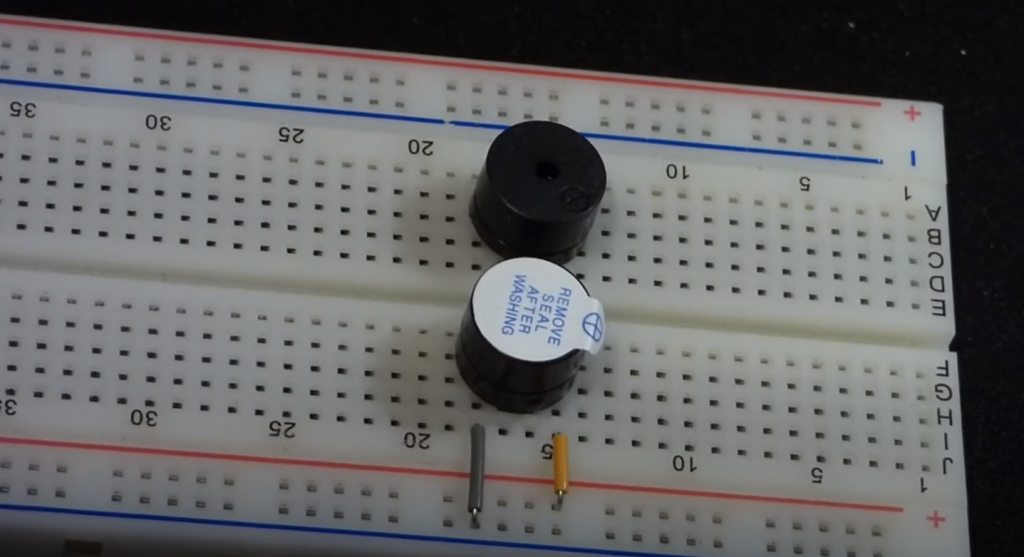

- Rapid prototyping of electronic devices

- Educational kits and projects in STEM learning

- Home automation systems and IoT products

- Building robotics projects

- Interactive art installations

- Environmental sensing and data collection

- Early-stage product testing and experimentation

Arduino’s versatility, approachability, and low cost have made it popular among hobbyists, students, artists, and startup companies. While microcontrollers like Arduino lack the power of more advanced industrial controllers, they enable innovative electronics projects and serve as accessible on-ramps to embedded system development.

Comparison between PLC and Arduino

Programmable Logic Controllers (PLCs) and Arduino are both widely used in automation but have important differences in capabilities and suitable applications.

Key Differences Between PLC and Arduino

While both are programmable microprocessor-based devices, PLCs and Arduino vary significantly:

- PLCs are industrial-hardened controllers designed to withstand electrical noise, vibration, extreme temperatures, and other harsh conditions. Consumer-grade Arduino boards are more fragile.

- PLCs use ladder logic programming familiar to plant engineers and technicians. Arduino uses the C/C++ language, requiring software skills.

- PLCs excel at real-time input scanning and deterministic output response critical for industrial processes. Arduino has much slower cycle times.

- PLCs can directly interface with industrial sensors, motors, contactors, drives, and communication buses. Arduino requires additional hardware and peripherals to integrate.

- PLCs have modular distributed I/O supporting large sensor and actuator networks. Arduino has limited I/O onboard the microcontroller.

- PLCs are ultimately more reliable and robust, with years of 24/7 operation expected. Arduino boards have a shorter working life.

Which is Better for Different Industrial Control Applications

PLCs are usually the preferred choice for complex automation systems, assembly lines, or hazardous environments. Their ruggedness, deterministic scanning and control, redundancy, and standard communications protocols are critical advantages.

For simpler machine control tasks, inexpensive automation stations, laboratory research setups, or prototypes, Arduino can provide a lower-cost yet functional alternative to PLCs. While lacking robustness and real-time performance, Arduino is sufficient for applications like data logging, simple sequences, and non-critical control.

Arduino may be incorporated as remote I/O expansion for a PLC to gain I/O point density in a compact form factor. But for the central coordinator and main control logic, PLCs are superior for larger, real-world industrial automation systems.

Memory Allocation

Both PLCs and Arduino boards utilize memory to store programs and data but differ in how memory is allocated and managed.

Memory Allocation in Arduino

Arduino boards contain Flash memory where the sketches (programs) are stored, SRAM (static random access memory) for storing variables when the program is running, and EEPROM for long-term data storage even when powered off.

The simple Arduino C/C++ programming environment does not require explicitly assigning memory locations. Dynamic memory allocation handles assigning SRAM for variables at runtime when needed. The Arduino IDE tracks usage and will warn if programs are close to exceeding available SRAM. EEPROM read/write functions allow storing and retrieving user data.

Memory Allocation in PLCs

PLCs have dedicated programs, data, and I/O memory regions. The PLC software must explicitly allocate memory for programs, internal bits/words, timers, counters, etc. Memory outside the ranges predefined for these functions cannot be accessed.

PLC programmers must track memory allocation for programs, tags, registers, timers, etc. Complex programs often require planning of data organization and memory mapping before implementation. Special memory areas are predefined for I/O modules.

Comparison of PLC and Arduino Memory Management

Arduino’s dynamic memory allocation makes program development easier compared to a PLC’s fixed memory mapping. However, the PLC’s stricter, static allocation provides determinism critical for industrial control programs. It ensures critical program components never get overwritten unintentionally.

The PLC’s capabilities make memory organization more predictable and reliable for complex industrial programs. The more basic Arduino memory architecture focuses on simplicity for beginners and shorter programs.

FAQ

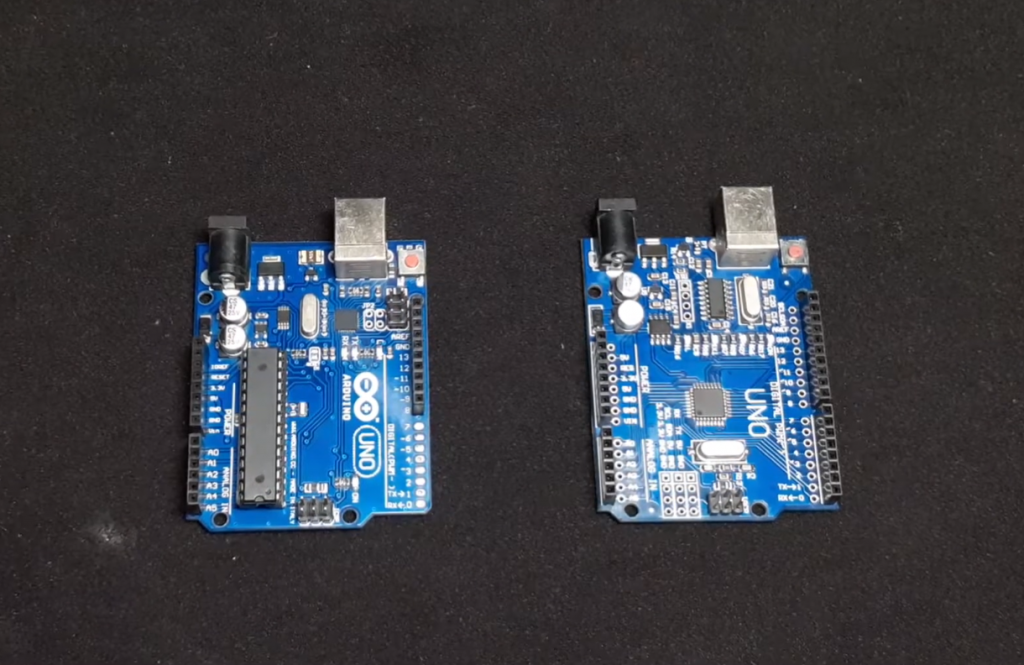

What are the key differences between PLCs and Arduinos?

The main differences between PLCs and Arduinos lie in their intended use cases, robustness, programming languages, and cost. PLCs are industrial controllers built to withstand harsh factory conditions like vibration, electrical noise, and extreme temperatures. They contain specialized processors optimized for scanning inputs, executing ladder logic, and updating outputs in real-time. PLCs are programmed in ladder logic, which electrical engineers and technicians are already familiar with. This makes them ideal for controlling industrial processes like assembly lines, machines, and robotics.

In contrast, Arduinos are inexpensive microcontroller boards made for hobbyists, prototyping, and educational use. They lack the ruggedness for most industrial deployments but provide more programming flexibility through the use of C/C++. Their ease of use and large community support make Arduinos well-suited for home automation, simple robotics projects, IoT devices, and rapid prototyping.

What are the advantages of PLCs over Arduino boards?

PLCs offer several advantages over Arduino boards, making them preferable for industrial use cases. Firstly, PLCs are highly rugged and reliable, able to withstand vibrations, electrical noise, and extreme temperatures unsuitable for consumer-grade Arduino boards. PLCs also provide deterministic, real-time performance critical for automation tasks. In addition, PLCs use ladder logic programming, which is familiar to electrical engineers and technicians. They also support common industrial communication protocols and have built-in security features like user authentication and remote access through VPN tunnels. Finally, PLC systems are highly scalable through distributed modular I/O and come with long product lifecycles and support from major manufacturers.

What are the advantages of using Arduino boards instead of PLCs?

Arduinos offer several advantages over PLCs, making them a better choice for certain applications. Firstly, Arduino boards are significantly cheaper than most PLCs. Arduinos also enable rapid prototyping and iteration at low cost. They provide more programming flexibility through the use of C/C++ instead of ladder logic. Arduinos are also beginner-friendly and have a large community knowledge base and support online. In addition, Arduino boards can be easily interfaced with numerous sensors, motors, and components, and their compact size makes them ideal for small spaces. Finally, Arduinos are great for education, given their low cost and accessibility.

When should I choose a PLC over an Arduino for a project?

It would help if you chose a PLC over an Arduino for any mission-critical industrial process where reliability and uptime are paramount. PLCs should also be chosen for systems that require real-time performance, deterministic execution, and very fast input/output scanning times. Applications in harsh industrial environments with lots of electrical noise, vibrations, extreme temperatures, or other hazards are also better suited to PLCs. In addition, applications requiring distributed I/O networks, regulatory compliance, or already using ladder logic are good PLC use cases. Finally, any project that needs to run 24/7 for years without reprogramming should choose a PLC for its longevity and reliability over time.

When is an Arduino the better choice over a PLC?

An Arduino is the better choice when you need an inexpensive, compact controller for projects not requiring industrial-grade reliability. Arduinos are great for quickly prototyping a design concept before implementation with a PLC. They also work well for projects with minimal I/O requirements that couldn’t justify the costs of a PLC. Arduinos are preferable for applications involving complex data analysis, math, algorithms, and floating point operations unsuited to ladder logic. Size-constrained applications requiring a compact controller can benefit from a small Arduino board over a larger PLC system. Finally, Arduinos are often the right choice for non-critical applications where occasional downtime is acceptable or short-lifespan projects where the lower costs of Arduino outweigh the longevity benefits of a PLC.

Related Video: Arduino VS PLC. Difference Between Arduino and PLC.

Summing Up

Both PLCs and Arduino have their strengths and weaknesses. PLCs are rugged, reliable, and optimized for industrial automation and control. They are programmed with ladder logic, which makes them familiar to electrical engineers. Arduinos are inexpensive microcontrollers good for prototyping and hobbyist projects. They have a large user community and are programmed in C/C++. PLCs are the better choice for most industrial applications due to their robustness and ladder logic programming. However, Arduino’s flexibility and low cost may make it a better option for simpler projects or quick prototyping. The right choice depends on the specific needs and constraints of the application.